A think-tank for Humor

By Dr Gorg Mallia Continue reading

Shattering women’s glass ceiling

The role of women in academia has always greatly interested me. Several years ago, when I was asked to become Gender Issues Committee chairperson at the University of Malta, I readily accepted. Apart from other tasks, the committee has just compiled a booklet about the profiles of senior female academics. Our objectives are twofold: one is to incentivise junior staff to aim higher and move forward in their career; the other, to help sensitise male colleagues to better appreciate the hurdles women face when pursuing an academic career together with raising a family.Continue reading

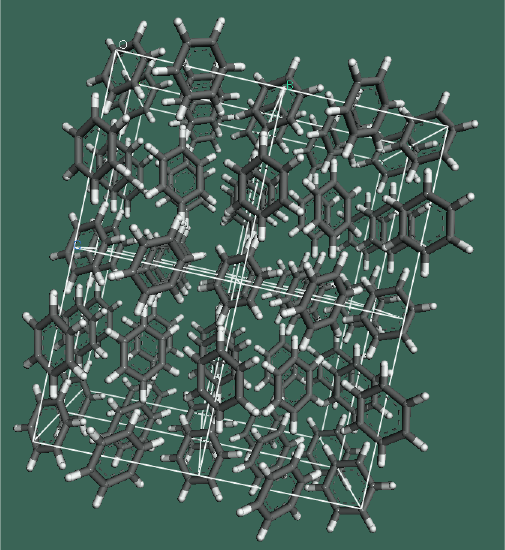

Playing with Solid State Benzene

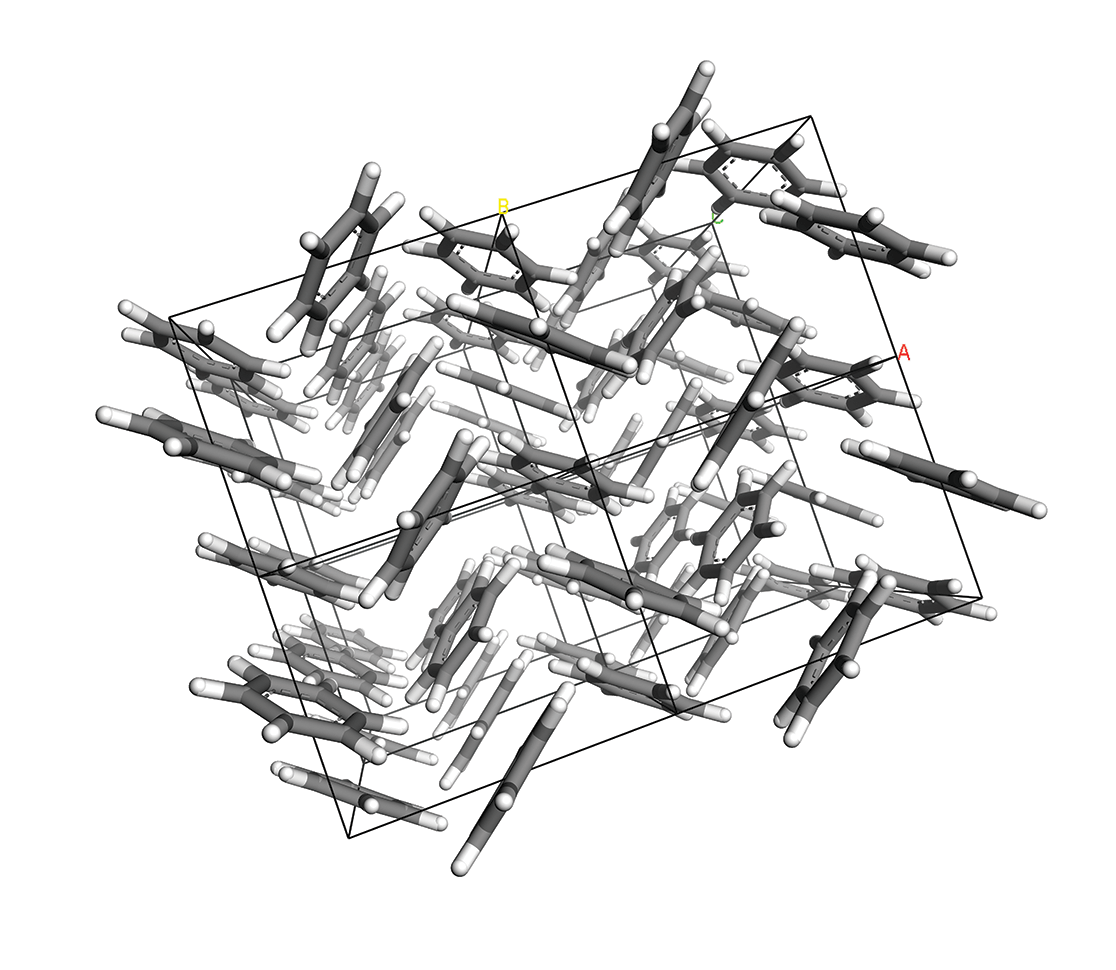

Computational chemistry is a powerful interdisciplinary field where traditional chemistry experiments are replaced by computer simulations. They make use of the underlying physics to calculate chemical or material properties. The field is evolving as fast as the increase in computational power. The great shift towards computational experiments in the field is not surprising since they may reduce research costs by up to 90% — a welcome statistic during this financial crisis.

Keith M. Azzopardi (supervised by Dr Daphne Attard) used two distinct computational techniques to uncover the structure of a carcinogenic chemical called solid state benzene. He also looked into its mechanical properties, especially its auxetic capability, materials that become thicker when stretched. By studying benzene, Azzopardi is testing the approach to see if it can work. Many natural products incorporate the benzene ring, even though they are not toxic.

The crystalline structures of solid state benzene were reproduced using computer modelling. The first technique used the ab initio method, that uses the actual physical equations of each atom involved. This approach is intense for both the computer and the researcher. It showed that four of the seven phases of benzene could be auxetic.

The second less intensive technique is known as molecular mechanics. To simplify matters it assumes that atoms are made of balls and the bonds in between sticks. It makes the process much faster but may be unreliable on its own due to some major assumptions. For modelling benzene, molecular mechanics was insufficient.

Taken together, the results show that molecular mechanics could be a useful, quick starting point, which needs further improvement through the ab intio method.

This research was performed as part of a Masters of Science in Metamaterials at the Faculty of Science. It is partially funded by the Strategic Educational Pathways Scholarship (Malta). This Scholarship is part-financed by the European Union – European Social Fund (ESF) under Operational Programme II –Cohesion Policy 2007-2013, “Empowering People for More Jobs and a Better Quality Of Life”. It was carried out using computational facilities (ALBERT, the University’s supercomputer) procured through the European Regional Development Fund, Project ERDF-080 ‘A Supercomputing Laboratory for the University of Malta’.

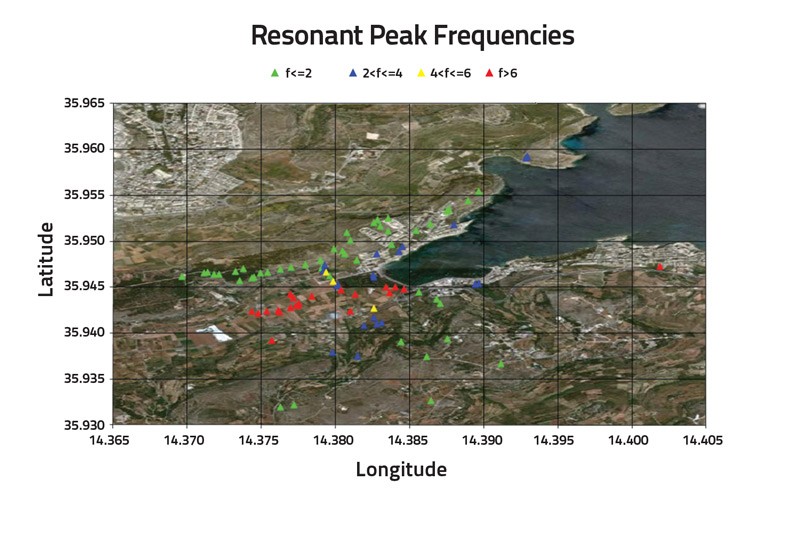

Xemxija and Earthquakes

On February 22, 2011, a magnitude 6.3 earthquake struck the city of Christchurch, New Zealand, killing 181 people and causing widespread destruction. Curiously, this damage was not evenly distributed, even for areas right next to each other. This phenomenon is called the site effect and depends on the underlying geology.

Malta, unlike New Zealand, is not typically associated with earthquakes. The islands lack a seismic building code and many structures could be damaged with moderate shaking. Malta’s past records list several earthquakes that have damaged buildings and even caused some to collapse. Apart from not being reinforced, buildings have been built on less stable ground, which increases risk.

Sharon Pace (supervised by Dr Pauline Galea) investigated this effect in one test area — Xemxija, in the north of Malta. She studied how sites in Xemxija would respond to the energy from an earthquake by using a portable seismograph to record ambient noise (caused by sea waves, vehicular traffic, and other anthropogenic sources) at over 100 points across the village (pictured). The ground’s surface can be considered a vibrating platform, which can be shaken both by ambient noise as well as stronger waves from earthquakes. The ground may “resonate” at particular frequencies, or not at all, depending on the kind of rock or soil layers making up the top 30 to 50 metres. Analysis of ambient noise shows if such resonance phenomena exist, how they are related to the local geology, and how this would translate into actual earthquake shaking.

At Xemxija, the study confirmed that the presence of clay (whether at the surface or buried) does amplify the grounds motion at certain frequencies. The results match previous studies in other areas, but this research went further by constructing geological models that can determine the ground’s underlying structure .

Taken together, the survey shows areas in Xemxija that might need extra support to survive future earthquakes and prevent deaths. Xemxija is not the only area with soft clay geology, the urbanised area of Mellieħa and historic citadel Mdina are built on top of similar structures. Considering the importance of these areas means that more studies are needed to better understand the structure of Maltese buildings and how they would respond to earthquakes.

This research was performed as part of a Masters of Science in Physics at the Faculty of Science. It was partially funded by the Strategic Educational Pathways Scholarship (Malta). This scholarship is part-financed by the European Union — European Social Fund (ESF) under Operational Programme II — Cohesion Policy 2007 – 2013, “Empowering People for More Jobs and a Better Quality of Life”.

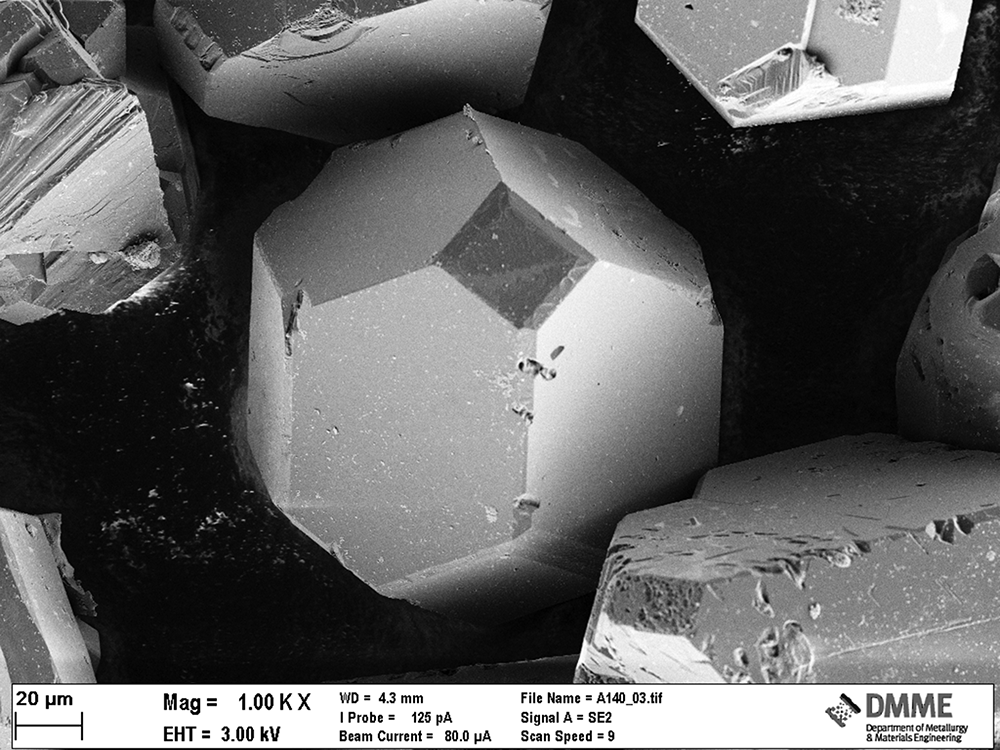

Scientific beauty of diamonds

Laptops and mobiles are smaller, thinner, and more powerful than ever. The drawback is heat, since computing power comes hand in hand with temperature. Macs have been known to melt down, catch fire and fry eggs — PCs can be even more entertaining. David Grech (supervised by Prof. Emmanuel Sinagra and Dr Ing. Stephen Abela) has now produced diamond–metal matrix composites that can remove waste heat efficiently.

Diamonds are not only beautiful but have some remarkable properties. They are very hard, can withstand extreme conditions, and even transfer heat energy faster than any metals. This ability makes diamonds ideal as heat sinks and spreaders.

The gems are inflexible making them difficult to mould into the complex shapes demanded by the microelectronics industry. By linking diamonds with other materials, new architectures can be constructed. Grech squashed synthetic diamond and silver powders together at the metal’s melting point. The resulting composite material expanded very slowly when heated. The material could dissipate heat effectively, and was cheaper and simpler to produce than current methods — a step closer to use on microchips.

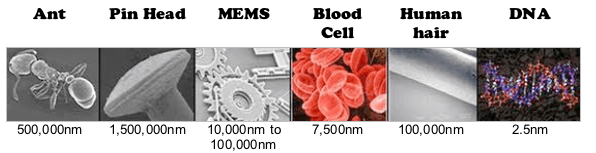

Grech’s current research is focused on obtaining novel types of interfaces between the diamond powders and the metal matrix. The new materials can improve the performance of heat sinks. New production techniques could help make these materials. By depositing a very thin layer of nickel (200 nanometres thick) on diamond powders using a chemical reaction, the gems would form chemical bonds with the layer while the metal matrix would form metallic bonds. The material would transfer heat quickly and expand very slowly on heating. A heat sink made out of this material would give us a cooler microprocessor and powerful electronics that does not spontaneously catch fire — good news for tech lovers.

This research was performed as part of a Bachelor of Science (Hons) at the Faculty of Science. It is funded by the Malta Council for Science and Technology through the National Research and Innovation Programme (R&I 2010-25 Project DIACOM) and IMA Engineering Services Ltd.

Future-Safe Malta

Words by Prof. Saviour Formosa

“Extreme weather leaves Mediterranean countries picking up the pieces. Egypt and Lebanon were the hardest hit with over 1.2 million people displaced overnight. Malta didn’t fare much better. The authorities have reported over 2,300 dead or missing, thousand injured and 74,000 persons displaced. Power cuts have been reported all over the island after Turbine Two tripped at the Delimara Power Station. Enemalta have not replied. The islands have taken a major blow to their infrastructure. Debris has been reported 1 km away from the coasts. The AFM and emergency responses were immediately dispatched and are starting to clear arterial roads. Insurance companies are still counting the costs. Valletta, Floriana and parts of Isla were protected from the storm surge by centuries-old Knight’s fortifications. The following localities have been affected: Birgu, Bormia, Kalkara, Marsa, Gzira, Msida, Pietà, San Giljan, Sliema, Ta’Xbiex, Xghajra, Birzebbuga, Marsascala, Marsaxlokk, Xlendi and Marsalforn. “

The above cutout could become reality if a Category 3 storm lashes Malta with 178 to 208 km per hour winds. The chances are minimal but too probable to ignore, since in 1995 a similar storm formed close to the Maltese Islands followed by others in 1996, 2006, and 2011. Below are two scenarios that compare Malta as it currently stands against an island with a solid disaster management plan.

[ SCENARIO 1 – AN UNPREPARED ISLAND]

The emergency forces have been inundated with calls for help and have few plans to operate a workable rescue effort. Key personnel were lost at home or while rushing to the scene, since the infrastructure has been knocked out, paralysing the island. Power surges or power cuts have caused fires all over the Islands creating an apocalyptic scenario. With the storm still raging, the lack of a back-end ICT network has rendered communication near impossible.

[ SCENARIO 2 – THE IDEAL SCENARIO]

A fleet of small aerial drones is monitoring the disaster. The authorities are using them to identify the hardest hit areas and map out corridors that allow access on the ground. Emergency vehicles are being deployed safely. Services will be redeployed after safety assessments and clearing of the main infrastructure. Paramedics, NGO rescue teams, and armed forces help move people to safer grounds and carry out rescue operations. Community buildings on higher ground are converted into temporary shelters. In turn, decision-makers are kept informed using an Emergency Room for effective relief.Continue reading

Labs in solution

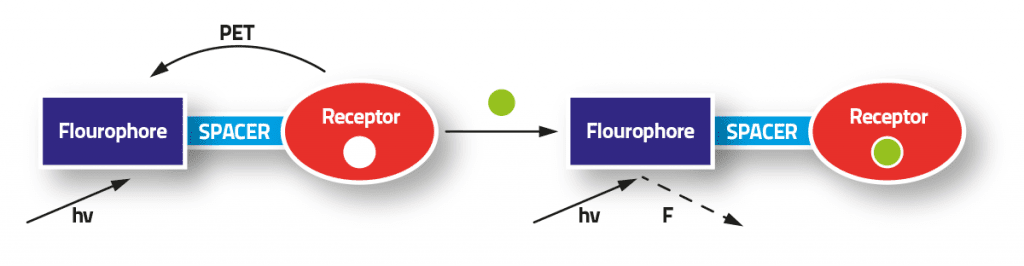

Imagine the smallest thing you possibly can. The eye of a needle? A human hair? A particle of dust? Think smaller, something you cannot even see, something on a molecular scale. Now imagine that molecule has the potential of a whole laboratory. This dream is now becoming a reality.

In recent years, the field of molecular sensors has grown into one of the most ground-breaking areas in Chemistry. Molecular sensors are compounds that can detect a substance, or unique mixture of substances, and provide an easily detectable output. Usually this is a change in the absorption of ultraviolet or visible light, or in the emission of Fluorescence. In other words: colours!

John Gabarretta (supervised by Dr David Magri) created a simple example of these fluorescent molecular sensors. The molecule was based on the Fluorophore-Spacer-Receptor model, where the ‘output’ part of the molecule (the fluorophore — a structure which shines light) is separated from the ‘input’ part (the receptor — a structure which is sensitive to a particular substance, such as acidity or a metal ion) by an intermediate spacer, whose main function is to link these two components together. The model means that a molecule can detect a chemical and respond by shining light or not. The process gives information about the chemicals in a solution.

The molecule was made by a two-step synthetic route (which took several attempts and resulted in several different colours), and its behaviour was tested by dipping into an acid. In water the molecule was switched ‘off’, but quickly turned ‘on’ in an acidic solution by giving a bright blue light when exposed to ultraviolet light (UV) — a pretty satisfying sight!

Molecular sensors have some very advanced applications — the pioneer A. P. de Silva said that there is room for a “small space odyssey with luminescent molecules”. This odyssey includes some that detect substances such as sugars.

While very advanced systems are approaching chemical computers, since they have multiple inputs and use Boolean Logic, the so-called ‘Moleculator’ or ‘gaming tic-tac-toe’ systems. The future is bright (if you pardon the pun) and with more complex structures more possibilities will appear; the molecular laboratory may become a reality detecting diseases or toxins in no time at all.

This research was performed as part of a Bachelor of Science (Honours) at the Faculty of Science.

An Intelligent Pill

Doctors regularly need to use endoscopes to take a peek inside patients and see what is wrong. Their current tools are pretty uncomfortable. Biomedical engineer Ing. Carl Azzopardi writes about a new technology that would involve just swallowing a capsule.

Michael* lay anxiously in his bed, looking up at his hospital room ceiling. ‘Any minute now’, he thought, as he nervously awaited his parents and doctor to return. Michael had been suffering from abdominal pain and cramps for quite some time. The doctors could not figure it out through simple examinations. He could not take it any more. His parents had taken him to a gut specialist, a gastroenterologist, who after asking a few questions, had simply suggested an ‘endoscopy’ to examine what is wrong. Being new to this, Michael had immediately gone home to look it up. The search results did not thrill him.

The word ‘endoscope’ derives from the Greek words ‘endo’, inside, and ‘scope’, to view. Simply put, looking inside our body using instruments called endoscopes. In 1804, Phillip Bozzini created the first such device. The Lichtleiter, or light conductor, used hollow tubes to reflect light from a candle (or sunlight) onto bodily openings — rudimentary.

Modern endoscopes are light years ahead. Constructed out of sleek, black polyurethane elastometers, they are made up of a flexible ‘tube’ with a camera at the tip. The tubes are flexible to let them wind through our internal piping, optical fibers shine light inside our bodies, and since the instrument is hollow it allows forceps or other instruments to work during the procedure. Two of the more common types of flexible endoscopes used nowadays are called gastroscopes and colonoscopes. These are used to examine your stomach and colon. As expected, they are inserted through your mouth or rectum.

Michael was not comforted by such advancements. He was not enticed by the idea of having a flexible tube passed through his mouth or colon. The door suddenly opened. Michael jerked his head towards the entrance to see his smiling parents enter. Accompanying them was his doctor holding a small capsule. As he handed it over to Michael, he explained what he was about to give him.

Enter capsule endoscopy. Invented in 2000 by an Israeli company, the procedure is simple. The patient just needs to swallow a small capsule. That is it. The patient can go home, the capsule does all the work automatically.

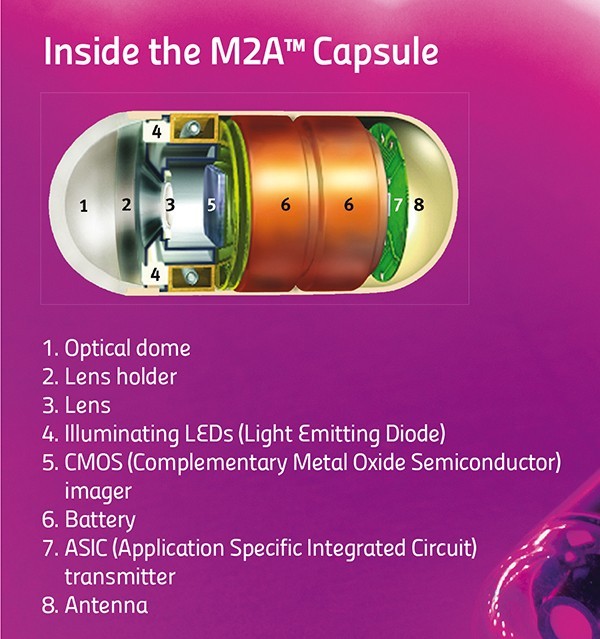

The capsule is equipped with a miniature camera, a battery, and some LEDs. It starts to travel through the patient’s gut. While on its journey it snaps around four to thirty-five images every second. Then it transmits these wirelessly to a receiver strapped around the patient’s waist. Eventually the patient passes out the capsule and on his or her next visit to the hospital, the doctor can download all the images saved on the receiver.

The capsule sounds like simplicity itself. No black tubes going down patients’ internal organs, no anxiety. Unfortunately, the capsule is not perfect.

“The patient just needs to swallow a small capsule. That is it. The patient can go home, the capsule does all the work automatically”

First of all, capsule endoscopy cannot replace flexible endoscopes. The doctors can only use the capsules to diagnose a patient. They can see the pictures and figure out what is wrong, but the capsule has no forceps that allow samples to be taken for analysis in a lab. Flexible endoscopes can also have cauterising probes passed through their hollow channels, which can use heat to burn off dangerous growths. The capsule has no such means. The above features make gastroscopies and colonoscopies the ‘gold standard’ for examining the gut. One glaring limitation remains: flexible endoscopes cannot reach the small intestine, which lies squarely in the middle between the stomach and colon. Capsule endoscopy can examine this part of the digestive tract.

First of all, capsule endoscopy cannot replace flexible endoscopes. The doctors can only use the capsules to diagnose a patient. They can see the pictures and figure out what is wrong, but the capsule has no forceps that allow samples to be taken for analysis in a lab. Flexible endoscopes can also have cauterising probes passed through their hollow channels, which can use heat to burn off dangerous growths. The capsule has no such means. The above features make gastroscopies and colonoscopies the ‘gold standard’ for examining the gut. One glaring limitation remains: flexible endoscopes cannot reach the small intestine, which lies squarely in the middle between the stomach and colon. Capsule endoscopy can examine this part of the digestive tract.

A second issue with capsules is that they cannot be driven around. Capsules have no motors. They tend to go along for the ride with your own bodily movements. The capsule could be pointing in the wrong direction and miss a cancerous growth. So, the next generation of capsules are equipped with two cameras. This minimises the problem but does not solve it completely.

The physical size of the pill makes these limitations hard to overcome. Engineers are finding it tricky to include mechanisms for sampling, treatment, or motion control. On the other hand, solutions to a third problem do exist. This difficulty relates to too much information. The capsule captures around 432,000 images over the 8 hours it snaps away. The doctor then needs to go through nearly all of these images to spot the problematic few. A daunting task that uses up a lot of time, increasing costs, and makes it easier to miss signs of disease.

A smart solution lies in looking at image content. Not all images are useful. A large majority are snapshots of the stomach uselessly churning away, or else of the colon, far down from the site of interest. Doctors usually use capsule endoscopy to check out the small intestine. Medical imaging techniques come in handy at this point to distinguish between the different organs. Over the last year, the Centre for Biomedical Cybernetics (University of Malta) has carried out collaborative research with Cardiff University and Saint James Hospital to develop software which gives doctors just what they need.

Following some discussions between these clinicians and engineers they quickly realised that images of the stomach and large intestine were mostly useless for capsule endoscopes.

Identifying the boundaries of the small intestines and extracting just these images would simplify and speed up screening. The doctor would just look at these images, discarding the rest.

Engineers Carl Azzopardi, Kenneth Camilleri, and Yulia Hicks developed a computer algorithm that could first and foremost tell the difference between digestive organs. An algorithm is a bit of code that performs a specific task, like calculating employees’ paychecks. In this case, the custom program developed uses image-processing techniques to examine certain features of each image, such as colour and texture, and then uses these to determine which organ the capsule is in.

Take colours for instance. The stomach has a largely pinkish hue, the small intestine leans towards yellowish tones, while the colon (unsurprisingly perhaps) changes into a murky green. Such differences can be used to classify the different organs. Additionally, to quickly sort through thousands of images, the images need to be compacted. A specific histogram is used to amplify differences in colour and compress the information. These procedures make it easier and quicker for algorithm image processing.

Texture is another unique organ quality. The small intestine is covered with small finger-like projections called villi. The projections increase the surface area of the organ, improving nutrient absorption into the blood stream. These villi give a particular ‘velvet-like’ texture to the images, and this texture can be singled out using a technique called Local Binary Patterns. This works by comparing each pixel’s intensity to its neighbours’, to determine whether these are larger or smaller in value than its own. For each pixel, a final number is then worked out which gauges whether an edge is present or not (see image).

Classification is the last and most important step in the whole process. At this point the software needs to decide if an image is part of the stomach, small intestine, or large intestine. To help automatically identify images, the program is trained to link the factors described above with the different organ types by being shown a small subset of images. This data is known as the training set. Once trained, the software can then automatically classify new images from different patients on its own. The software developed by the biomedical engineers was tested first by classification based just on colours or texture, then testing both features together. Factoring both in gave the best results.

“The software is still at the research stage. That research needs to be turned into a software package for a hospital’s day-to-day examinations”

After the images have been labeled, the algorithm can draw the boundaries between digestive organs. With the boundaries in place, the specialist can focus on the small intestine. At the press of a button countless hours and cash are saved.

The software is still at the research stage. That research needs to eventually be turned into a software package for a hospital’s day-to-day examinations. In the future, the algorithm could possibly be inserted directly onto the capsule. An intelligent capsule would be born creating a recording process capable of adapting to the needs of the doctor. It would show them just what they want to see.

Ideally the doctor would have it even easier with the software highlighting diseased areas automatically. The researchers at the University of Malta want to start automatically detecting abnormal conditions and pathologies within the digestive tract. For the specialist, it cannot get better than this.

The result? A shorter and more efficient screening process that could turn capsule endoscopy into an easily accessible and routine examination. Shorter specialist screening times would bring down costs in the private sector and lessen the burden on public health systems. Michael would not need to worry any longer; he’d just pop a pill.

* Michael is a fictitious character

[ct_divider]

The author thanks Prof. Thomas Attard and Joe Garzia. The research work is funded by the Strategic Educational Pathways Scholarship (Malta). The scholarship is part-financed by the European Union — European Social Fund (ESF) under Operational Programme II — Cohesion Policy 2007–2013, ‘Empowering People for More Jobs and a Better Quality of Life’

Insects in Malta

Insects are vital. Insects also cover the planet, with local research showing that there might be over 6,000 species — a wonderful world awaits. Find out about the incredible world of insects in Malta!

Continue reading