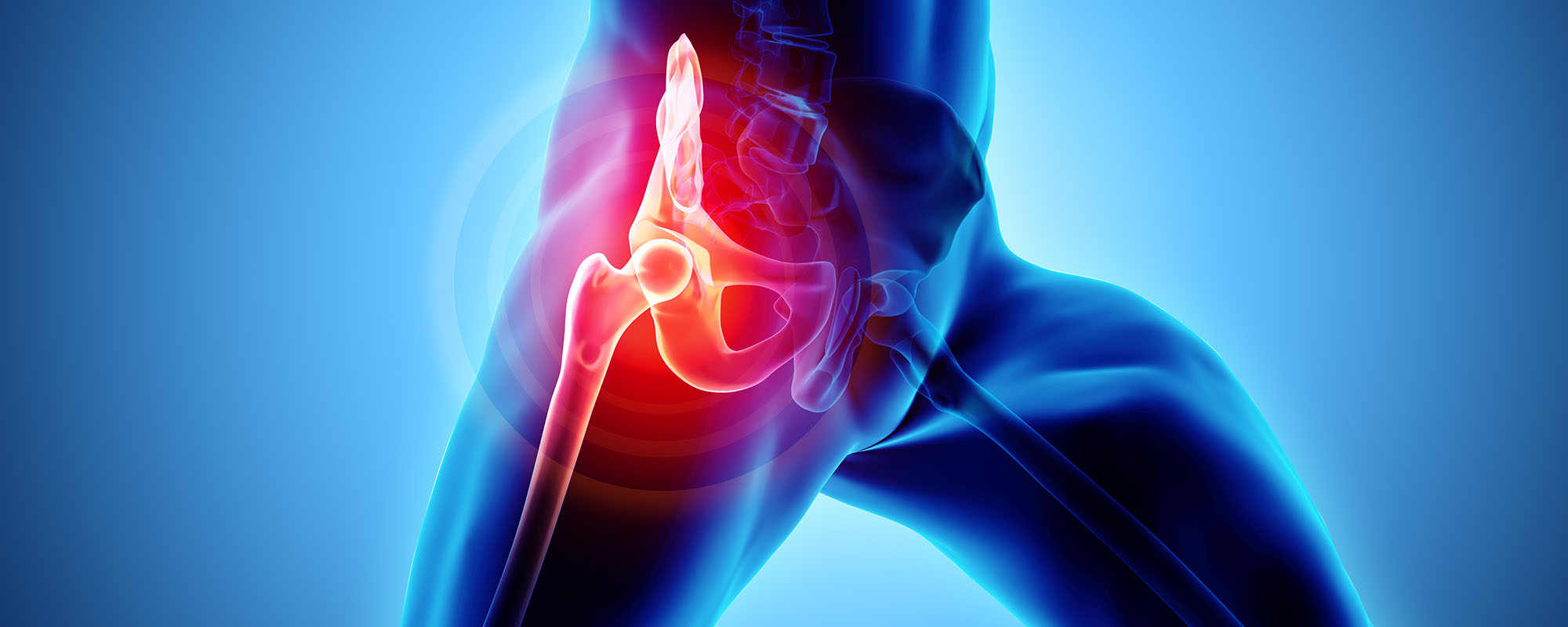

The earliest recorded attempts at hip replacement date back to 1891. At the time, ivory was proposed to replace the femoral heads of patients whose hip joints had been destroyed by tuberculosis. Since then, everything changed. THINK speaks to the MaltaHip Team to learn about their innovative hip replacement technology.

Continue readingTiny Sensors, Big Impact: Revolutionising Air Quality Monitoring with Cutting-Edge Tech

With the rising population density and increasing number of cars on the roads, monitoring air quality is essential. As technology advances, sensors play a crucial role in detecting harmful substances in the air. However, most sensors are bulky, costly, and limited to industrial use. The University of Malta is working to develop smaller, more affordable, and accessible alternatives.

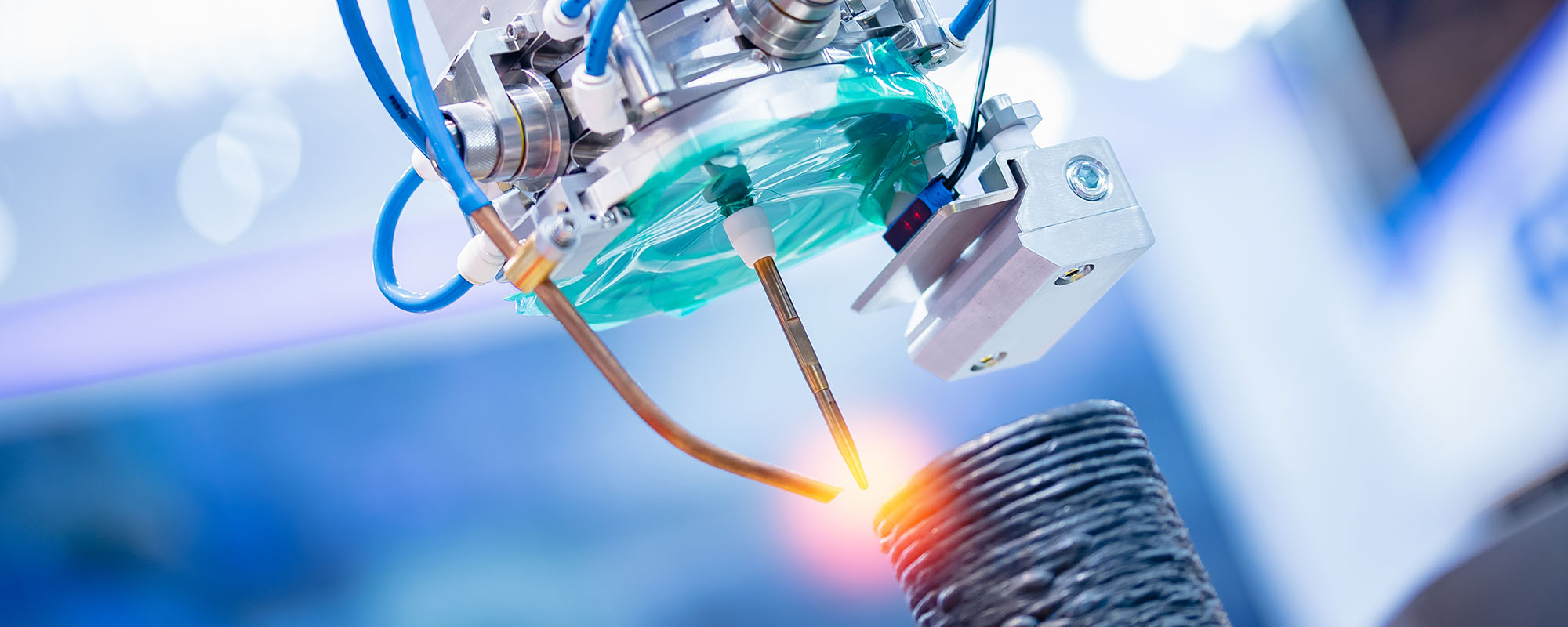

Continue readingSmooth Operator: Improving Surface Finish in Additive Manufacturing

While the advent of 3D metal printing may redefine how designers develop parts for products, the process itself is not without faults. Andre Giordimaina speaks with THINK about the GLAM Project, which aims to improve the process of 3D metal printing by optimising the finish and performance of designed parts.

Continue readingA Decade of Open Access at UM

This year marks a significant milestone for UM as we celebrate the 10th anniversary of OAR@UM, the University’s Open Access Repository. Its role reflects UM’s commitment to enhance the visibility and dissemination of research output generated at UM.

Continue reading3D Printing Balloons Inflates Enthusiasm for Future Technology

With the rise in popularity of 3D printing, the medium has become more accessible. What’s more, recent advancements in the field have made the technology rather intriguing. THINK explores the latest UM research on the development of 3D-printed balloons.

Continue readingDesigning the Next Dimension: An Insight into 3D Printing Innovation

3D printing can be an expensive sector to get into, but SPELL3D’s solution can help peel back some costs by combining the advantages of two styles of printer.

Continue readingMEGALITH: An Investigation Into The Conservation of Our Megaliths

The Maltese Islands are home to some of the world’s oldest megaliths. Yet, continuous exposure to the elements has caused ongoing stone degradation.

Continue readingGreen Walls: A Sustainable and Innovative System to Reduce the Impact of Pollution

In cities, pollution remains a pressing environmental concern for pedestrians. THINK sits down with Prof. Ing. Daniel Micallef and Dr Edward Duca from UM, who are using plants and physical barriers to combat traffic-generated pollution.

Continue readingADACE3 – Revolutionising Bookkeeping with AI

Filling in an FS3 form (Statement of Earnings/Tax Return forms) is already a headache, but imagine trying to prepare accounts for a small business. It is a time-consuming and laborious process, and doing things by hand can lead to serious mistakes. Why haven’t we automated accounting yet?

Continue readingface:LIFT: Using Text Descriptions to Create Photo-Realistic Faces

Imagine creating photo-realistic images of faces using only text descriptions. This innovative UM software is now freely available to the public!

Continue reading