Scientific beauty of diamonds

Laptops and mobiles are smaller, thinner, and more powerful than ever. The drawback is heat, since computing power comes hand in hand with temperature. Macs have been known to melt down, catch fire and fry eggs — PCs can be even more entertaining. David Grech (supervised by Prof. Emmanuel Sinagra and Dr Ing. Stephen Abela) has now produced diamond–metal matrix composites that can remove waste heat efficiently.

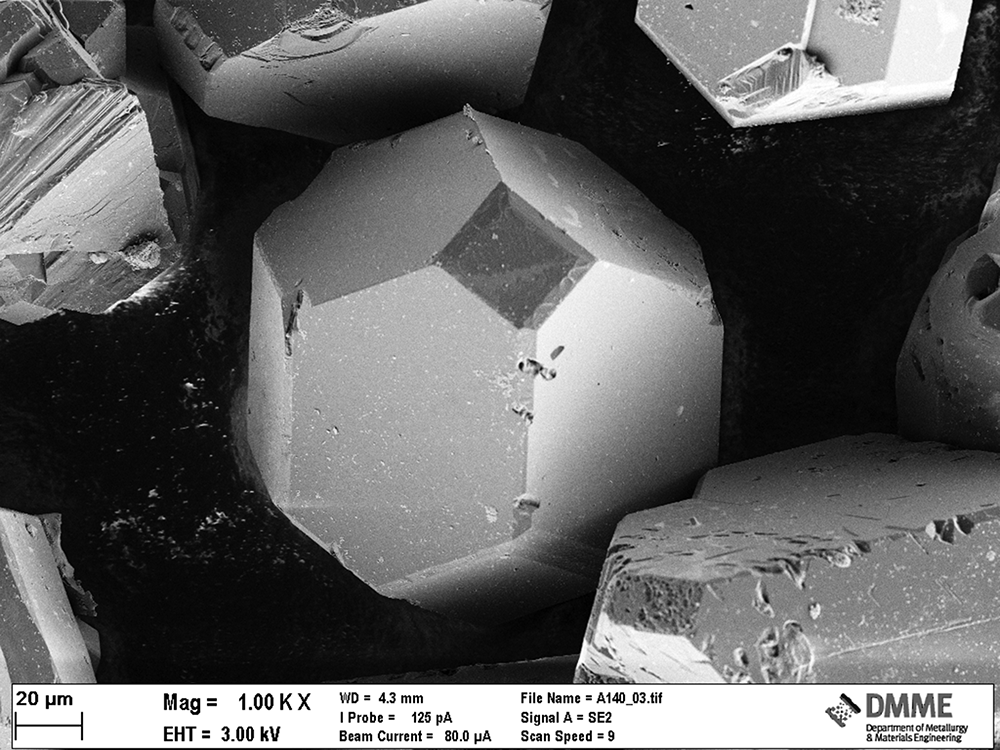

Diamonds are not only beautiful but have some remarkable properties. They are very hard, can withstand extreme conditions, and even transfer heat energy faster than any metals. This ability makes diamonds ideal as heat sinks and spreaders.

The gems are inflexible making them difficult to mould into the complex shapes demanded by the microelectronics industry. By linking diamonds with other materials, new architectures can be constructed. Grech squashed synthetic diamond and silver powders together at the metal’s melting point. The resulting composite material expanded very slowly when heated. The material could dissipate heat effectively, and was cheaper and simpler to produce than current methods — a step closer to use on microchips.

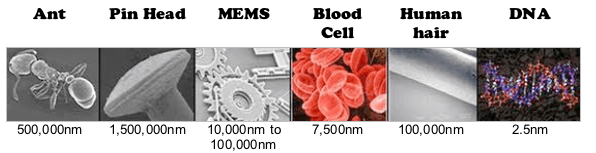

Grech’s current research is focused on obtaining novel types of interfaces between the diamond powders and the metal matrix. The new materials can improve the performance of heat sinks. New production techniques could help make these materials. By depositing a very thin layer of nickel (200 nanometres thick) on diamond powders using a chemical reaction, the gems would form chemical bonds with the layer while the metal matrix would form metallic bonds. The material would transfer heat quickly and expand very slowly on heating. A heat sink made out of this material would give us a cooler microprocessor and powerful electronics that does not spontaneously catch fire — good news for tech lovers.

This research was performed as part of a Bachelor of Science (Hons) at the Faculty of Science. It is funded by the Malta Council for Science and Technology through the National Research and Innovation Programme (R&I 2010-25 Project DIACOM) and IMA Engineering Services Ltd.