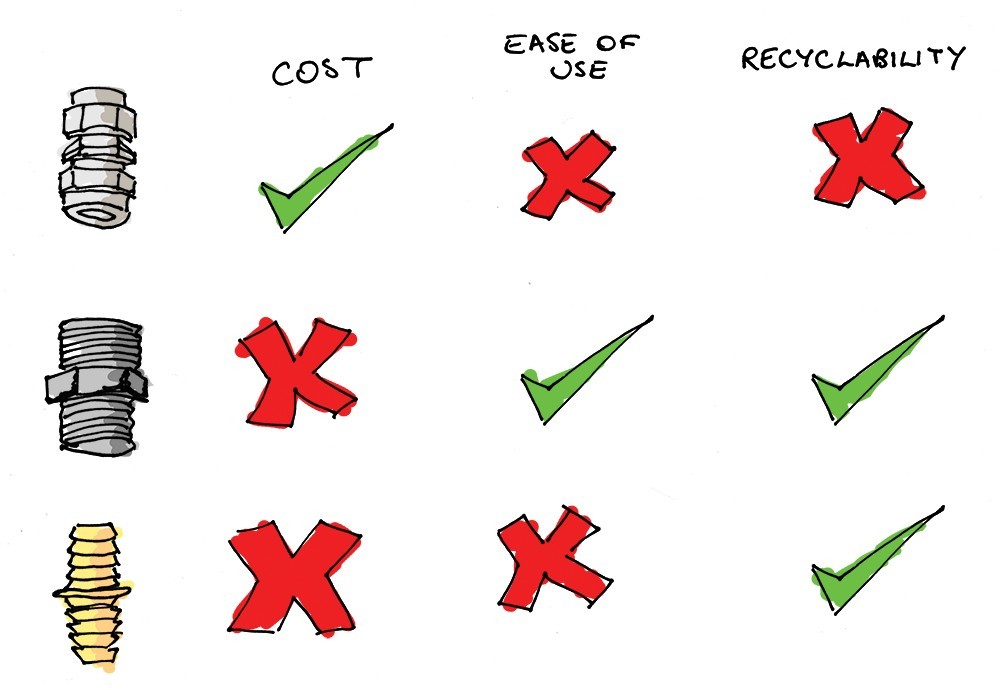

Taking the right decision can be a very challenging and daunting process. Designing a mobile phone, a makeup case, or even a pipe needs engineering teams to continuously make important choices quickly. Lawrence Farrugia (supervised by Prof. Jonathan C. Borg) developed a framework that helps engineers evaluate concepts and take these decisions practically. In a typical design process, the design team generates a number of different concepts that fulfil what is needed from the product. These design concepts are then evaluated against conflicting evaluation criteria. Criteria are chosen from the life cycle of the product and can include cost, quality, ease of use, and recyclability (pictured). Evaluation determines the concept chosen for further development.

Although there are design tools that are intended to support engineering design teams in decision making, the reality check is that these tools are rarely used. Such tools are typically too impractical to employ in the real world. Due to the ever increasing complexity of products and the importance of early decision making, this research recognised the need to provide engineering design teams with a practical yet reliable support system.

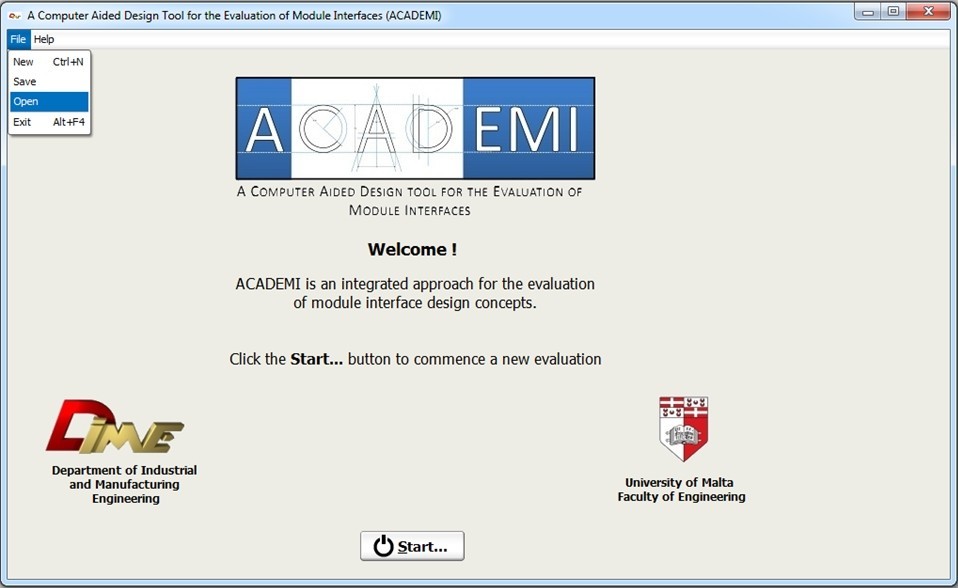

Farrugia’s research was carried out at the Concurrent Engineering Research Unit (CERU) within the Faculty of Engineering. The framework he developed aids design teams to analyse and rank multiple design concepts against several conflicting evaluation criteria. The proposed framework was then implemented into a prototype computer aided design (CAD) tool named ACADEMI (pictured).

The tool developed by Farrugia allows for design concepts to be mathematically appraised and ranked automatically. The user inputs the various evaluation criteria and the best design is shown in a very short time. This ranking helps the design team rapidly figure out which design concepts should be developed. After the framework and tool were developed the research work was evaluated in the field by engineers from industry and academia. Most industry personnel said that they would be willing to adopt the computer tool in their daily professional work. ï

More information about the research work may be accessed through: www.academi.co.nr

This research was performed as part of an M.Sc. (Research) in Mechanical Engineering at the Faculty of Engineering. This research was partially funded by the Strategic Educational Pathways Scholarship (Malta). This Scholarship is part-financed by the European Union — European Social Fund (ESF) under Operational Programme II — Cohesion Policy 2007–2013, ‘Empowering People for More Jobs and a Better Quality Of Life’.

After repeatedly visiting Asia, I totally disagree with comments occasionally made that China’s industrial success is wholly attributed to its ability to replicate low quality versions of branded products at rock-bottom prices. In China there are many good examples of good quality products and brands being produced such as Audi, Airbus, and Armani. Based on these facts, what Maltese industry and policy makers should focus on is making our industry more competitive by improving the current situation and analyzing products being developed elsewhere.

After repeatedly visiting Asia, I totally disagree with comments occasionally made that China’s industrial success is wholly attributed to its ability to replicate low quality versions of branded products at rock-bottom prices. In China there are many good examples of good quality products and brands being produced such as Audi, Airbus, and Armani. Based on these facts, what Maltese industry and policy makers should focus on is making our industry more competitive by improving the current situation and analyzing products being developed elsewhere.