In our modern, fast-paced lives, more of us are turning to convenient ready-to-eat meals. But with short shelf lives and high demand, food safety tests just aren’t quick enough anymore. Dr Sholeem Griffin tells Becky Catrin Jones how an innovative collaboration between microbiology and computing is tackling this challenge.

Let’s be honest: very few of us make our lunch from scratch every single day. Although meal prepping trends are slowly catching on, bags of ready-to-eat salad, dips, and cheeses remain very tempting—especially when they can stop you from consuming last week’s lasagne. Such convenient healthy choices mean that we don’t need to think as hard about what’s going into our lunchbox. But is this food-on-the-move culture really as healthy as it seems? As with all perishables, bacteria and fungi will slowly multiply on your food long before you actually see anything ‘growing’ on them. With most things, this can be controlled at production thanks to batch testing which screens for any pathogens that could develop into bigger problems later on. This happens with ready-to-eat foods too; the trouble is that turn-around on the results cannot keep up with production. The way these tests are conducted in pre-packed foods also differs—assessing batches rather than individual items. This means that foods are often already in our shops and fridges when a problem is identified. In these cases, suppliers have to recall the items, resulting in both angry customers and serious fiscal repercussions.

The need to speed up this analytic and laborious microbial process is clear. But if culture tests performed in food safety checks aren’t quite making the cut, what else can be done? Biomedical engineers Dr Owen Falzon and Prof. Kenneth Camilleri, and quantitative microbiologist Prof Vasilis Valdramidis from the University of Malta are working with local dairy product producer Farm Fresh Ltd. on a new method of online testing. Rather than waiting a week for bacterial culture results, why not determine what might be growing on the food right now? Their idea combines a novel imaging technique with new algorithms to produce a real-time map of any bacterial or fungal growth. This is possible through a technology known as hyperspectral imaging.

Hyperspectral imaging

Hyperspectral cameras and the DSLR you take on holiday work similarly, making use of light at different wavelengths to produce a picture. While your camera can only pick up what your own eyes can see, visible light with wavelengths between 450 and 700 nanometers (nm), hyperspectral imaging can record a far wider range. This means that visual and infrared light can all be picked up by the same system. Microbes, the common term for all bacteria or fungi that grow on our food, can reflect light at these higher wavelengths. By scanning the products with this light, one should be able to see exactly where the microbes are.

With this idea and some funding support from MCST, Falzon and Valdramidis identified a capable young scientist who was up for the challenge. Dr Sholeem Griffin was on the lookout for a project that would bring her a wealth of new skills. ‘I started looking for postdocs in Malta. When this one came up it really appealed to me, and luckily I got it!’ she says.

Griffin’s PhD was in immunology and metabolism, studying infertile dairy cows and ways to encourage milk production. With a background in general microbiology and molecular techniques, she was keen to undertake a project that would combine this experience with the opportunity to learn more about coding and high-performance bioinformatics—both essential expertise for a future life scientist.

When starting a new project, it is critical to get a good grasp of the field by spending some time reading literature on the topic. Griffin thought she would have at least a week or two after arriving in Malta to get the required reading under her belt and get going. But reality trumped expectations in this case. ‘When I arrived, my first instruction was to learn how to make ġbejna,’ Griffin recalls with a smile. ‘So I spent the first few weeks making cheese, feeding it to people and getting them to compare it to shop-bought ġbejna to work out whether I was on the right track. It was good fun!’

And so the food microbiology lab at the Faculty of Health Sciences at Mater Dei turned into a mini cheese-production plant where Griffin tried to work out a way to make reproducible cheese in a sterile environment. Making ġbejna takes around two days, and the cheese can then be matured for as long as desired for it to acquire its unique flavour. Unpasteurised milk is combined with rennet and bacteria called lactobacilli. With some mixing and incubating, these combine to make curds, paving the way for the cheese. This mixture is then potted in small slotted cups and left to drain for around 24 hours. Cheeselets are given another 24 hours to dry, and can then be used for study.

But if the cheese is produced in a sterile lab, surely we shouldn’t see any microbial growth? ‘The important thing to note is that ġbejna is made from unpasteurised milk,’ highlights Griffin. ‘The milk is not sterile, so no matter what conditions the cheeselet is kept in, things will start cropping up after about a week.’

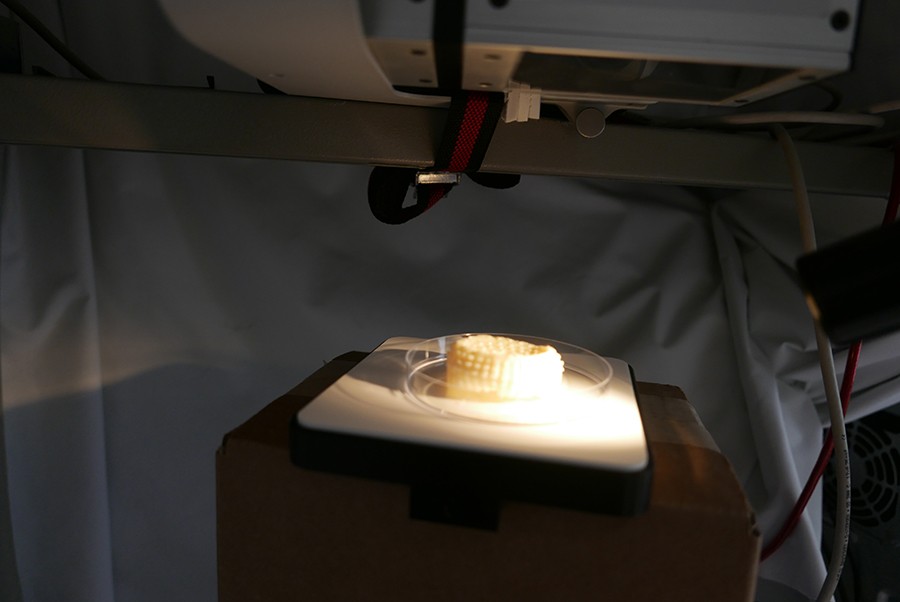

When this happens, the cheese can be scanned using the hyperspectral imaging techniques. Light emission is recorded from all around the item and combined so as to give as much information as possible. The aim is to differentiate clean from contaminated cheese, and then identify which organism might be causing the problem. Scanning in this way produces masses of data which needs to be collected and sorted into a format that is easier to understand. This is where the coding comes in.

Griffin and Falzon are developing algorithms to analyse the data, turning a mass of numbers into a much more consumable format. These algorithms can be adapted based on the subject food and can account for the presence of bacteria that we know belongs on the cheese. ‘There’s no use flagging up lactobacilli for example, when without it we wouldn’t get cheese production in the first place!’ says Griffin.

The plan is to have these readings translated in real time and use them to spot any differences while each cheeselet is being scanned. However at such an early stage in the project, the main challenge for Griffin is understanding how to write code specific to the question at hand: ‘My greatest achievement at the end of the project will be to look back and say that I have conquered some coding,’ Griffin notes.

Projects like this provide the opportunity for young scientists to learn and move with the changing climate

Dr Sholeem Griffin

Hyperspectral imaging is not a foreign concept to food production industries; it is already used to distinguish tainted from edible fruits and to highlight any damaged areas during processing. Applying this on a microscopic level is what’s new and exciting. But what makes this project really unique is the complex algorithms that are written to make sense of all this data. ‘The collaboration between IT and life sciences is still not commonplace,’ Griffin remarks. ‘Projects like this provide the opportunity for young scientists to learn and move with the changing climate.’

It’s still early days and this project has a long way to go before mass food production can be revolutionised by hyperspectral imaging. But with such a sound theory and an enthusiastic collaboration between (micro)biology and computing, it’s hard to imagine that we won’t all be scanning our salads for unwanted colonies in the near future.

The Food Inspection using Hyperspectral Imaging’ (FIHI) project is financed by the Malta Council for Science and Technology and on behalf of the Foundation for Science and Technology through the Fusion: R&I technology Development Programme.

Comments are closed for this article!