Electron Beam Melting (EBM) is a state of the art manufacturing process. Using this process product designers will be limited only by their imagination. This technology uses an additive manufacturing approach where parts are built layer by layer — think of ‘3D printing’. It can use exotic metals like titanium alloys, however it does have limitations such as producing a rough surface finish that hampers its functions.

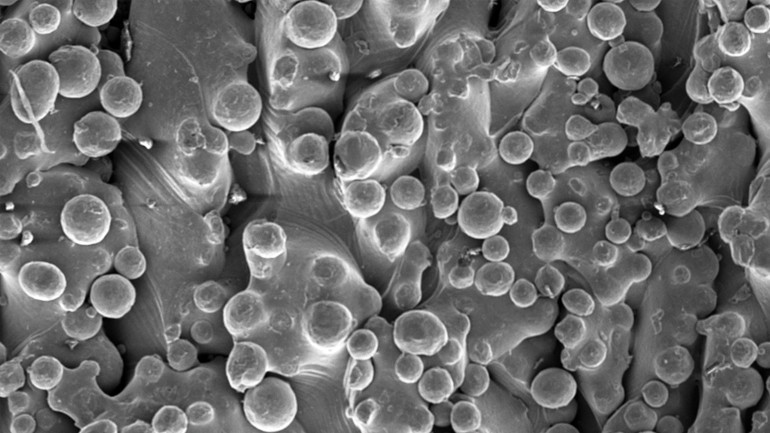

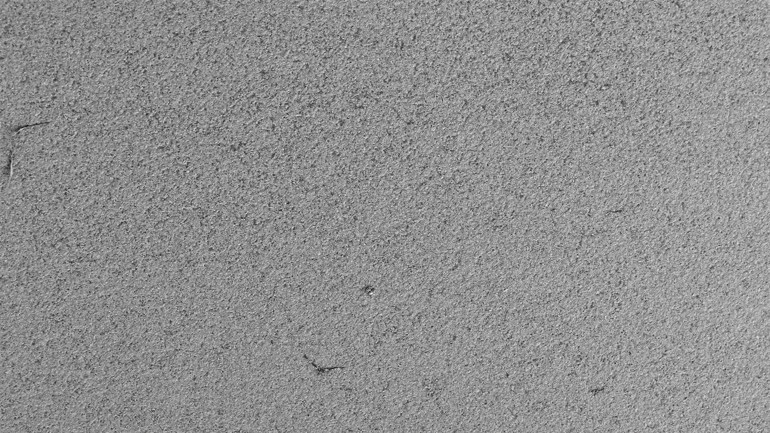

Christian Spiteri (supervised by Dr Arif Rochman) investigated whether the Electric Discharge Machining process can be used to finish parts produced using EBM to give a smooth surface (difference pictured). He treated titanium products with the Electric Discharge Machining process and microscopy showed that the finished surface consists of a set of micro-craters instead of rough grains. By adding the finishing process, more complex geometries could be created. Overall, adding Electric Discharge Machining to EBM had many benefits.

Dr Arif Rochman (University of Malta) said, ‘EBM parts can be used for a wide range of applications such as implants in the medical sector or complex tool inserts, […] which cannot be manufactured using conventional methods. Understanding the synergy between both processes is a must for product designers and process engineers to be able to manufacture high quality EBM products.’

This research was performed as part of a M.Sc. (Res) in Mechanical Engineering at the Faculty of Engineering. This research was partially funded by the Strategic Educational Pathways Scholarship (Malta). This Scholarship is part-financed by the European Union – European Social Fund (ESF) under Operational Programme II – Cohesion Policy 2007-2013, ‘Empowering People for More Jobs and a Better Quality Of Life’.

Comments are closed for this article!