Seifert Systems is a German family business with over 50 years of experience in designing and manufacturing thermal management products. With its operation set up in Malta decades ago by Engineer Rolf Seifert, it has grown into the renowned business it is today, operating as a globally recognised company. Recently, Seifert made the news for Malta’s first Zero Carbon Footprint factory. In exploring Seifert’s journey to carbon neutrality (and in light of Europe and Malta’s ambitious net zero targets for 2050), the opportunity arises to set an example for other manufacturing companies to follow.

Definition: A zero carbon footprint for a manufacturing company signifies that the organisation operates in a manner where its activities result in no net release of carbon dioxide into the atmosphere. This is achieved through a combination of actions, including minimising carbon emissions in production processes, sourcing renewable energy, implementing energy-efficient practices, and offsetting any remaining emissions through measures such as carbon sequestration or the purchase of carbon credits.

Speaking to Philipp Seifert, the Production Operations Manager, the first question regards how the company first decided to begin its carbon neutrality journey. What was it that prompted it? Philipp turned the clock back, stating that Seifert has always been ahead of the curve when it comes to environmental responsibility. Specifically, he says that 27 years ago, Seifert made its first big investment in machinery and equipment with a focus on sustainability. Instead of wasting a lot of water on cleaning during the manufacturing process, a state-of-the-art closed loop washing system was set up to recycle the water used.

‘Generally, companies deal with waste water by having a drainpipe in the floor. The principle there is out of sight, out of mind. But as a company, we have always tried to be more conscious and responsible in a lot of situations, making that big initial investment, which eventually, aside from being the right thing to do, ends up saving money.’

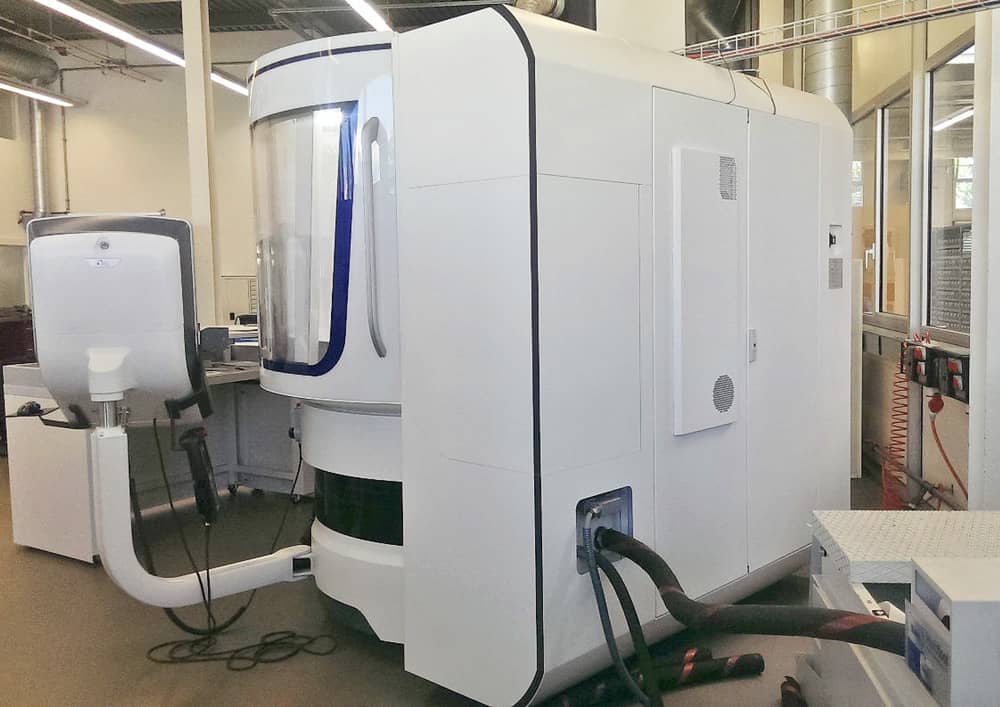

When it comes to the topic of carbon neutrality specifically, Philipp states that the process began through an interaction with one of their customers, DMG Mori, a multinational German-Japanese manufacturer of machine tools. DMG Mori sent out a questionnaire to their supply chain, asking a range of questions to get an idea of how sustainable it was.

‘DMG Mori are at the very high end of the market in terms of price and quality. The questionnaire they sent us was on a platform of theirs, asking the usual questions to check if we were socially and environmentally conscious and to check if we were carbon neutral. We were encouraged by their purchasing manager to look into the questionnaire seriously. The engineer who built the closed loop water efficiency system at Seifert looked into it, and we ended up deciding to explore carbon neutrality in more depth. We wanted to fulfil DMG Mori’s standards to the highest possible degree. We saw the scope and recognised the opportunity.’

Embarking on the Journey

By researching the implications of carbon neutrality for their business, Seifert realised how valuable it could be. Aside from saving on energy bills, Seifert would be a leader in the market, and would thus also be extremely competitive. Leading companies like DMG Mori, who were trying to green their supply chain due to pressures such as Environmental, Social and Corporate Governance (ESG) and corporate sustainability reporting, would want to deepen their relationship with Seifert.

Philipp explains that Seifert started an arduous 6-month process to try and get an understanding of Seifert’s environmental footprint. They had one person dedicated entirely to this task, in addition to hiring outside consultants. The process involved an extreme level of data collection, for example, requiring an inventory of all purchased IT equipment. This included the number of printers, what kind of ink they used, how many computers had webcams. The audit even wanted to know if Seifert’s computers used a wireless mouse, because of the need to take note of the batteries which go into them.

‘The first step in our journey to carbon neutrality was intense. In 2021, we finally achieved the certification. It was not an easy journey, however, as we encountered a lot of bureaucratic obstacles. The 2800 solar panels we installed in 2015, for example, could not count towards our carbon neutrality because they were using the feed-in tariff. So to a degree, we had to also buy carbon offsets. That’s sometimes a bit of a touchy subject, as some companies have issued these certificates while doing nothing. We buy UN-certified certificates on a German exchange with verified projects. Generally, we try to vet and choose individual projects. Currently, this is the only option we have, but every year, we rely on offsets less and less as we continue to invest in energy efficiency.’

Achieving Net Zero Carbon

When asking Philipp what investments were made to make the factory more energy efficient and achieve carbon neutrality, he indicated that the biggest energy savings have been achieved by replacing old, inefficient equipment with new ones that can produce much higher quantities of material using a similar amount of energy. One of the biggest investments was in a sheet metal machine which proved four times more productive.

Another strategy which Seifert employed was to take a systems approach. The company identified the processes in the factory which consumed the most energy, and found ways to combine them to avoid wastage and repetition. For example, they managed to combine their air compression system with their water heating system. Compressed air, a vital resource in many manufacturing processes, consumes a great deal of energy and generates a lot of waste heat. At the same time, Seifert’s water heating system is needed because hot water is required in other parts of the manufacturing process.

‘If you’ve ever been around an air compressor room, it is hot as hell. There are fans which cool the compressor, resulting in a lot of hot air being blown into the surrounding area as a byproduct. So we realised that we could use that waste heat. We got a compressor with a built-in heat exchanger. By combining systems, we will be saving more and more energy by letting none of it go to waste. The plan is to then tap into other machinery in a similar way. It is a holistic approach.’

Main Challenges

When asked what the main challenge was to achieving carbon neutrality, Philipp says that initially, it was a question of selling the concept to people in the company. Not everyone was convinced that it made business sense to embark on the journey. However, the Group CEO was fully behind it, and so everyone ultimately pulled the same rope. Once it was actually implemented, everyone immediately began to see the benefits. Seifert was visited by the President of Germany during a visit to Malta, as he wanted to visit a German business while in Malta, and because of Seifert’s carbon neutrality, he was taken there as a leading local example.

The main challenge, Philipp says, aside from a lack of local skills or familiarity with the concept, was the need for a change in institutional culture. He thinks the Maltese business community still has not fully grasped the opportunity which carbon neutrality presents for them. While going carbon neutral is the right thing to do, it also makes business sense. Not just because of the energy savings, but again, Philipp says, because of how it makes other businesses want to engage.

‘Seifert has customers who say that by going carbon neutral, Seifert is helping them to green their supply chain, and thus it makes them more competitive as well. It is a net positive for clients and customers alike. The majority of Seifert’s business partners state that it is an upcoming requirement for them that their suppliers are making these kinds of investments. Since Seifert is still one of the few companies ahead of the curve in this regard, it gives them a huge advantage, as sometimes, they are the only business who can claim to be carbon neutral.’

Philipp adds that even companies in the United States who are not aligned with ESG or who are climate sceptics, still find they are obliged to follow new environmental standards. Therefore, they still need to buy into the concept and prefer to work with Seifert.

While going carbon neutral is not the end of a journey but rather a major step which entails ongoing investments in energy efficiency, it has evidently already reaped huge benefits for Seifert. It presents an opportunity for the wider Maltese business community also, especially at a time when Europe’s manufacturing strategy shifts towards bringing manufacturing back home, to make supply chains more resilient and more environmentally responsible. The transformation will require upskilling and a change in institutional culture, but Seifert shows that it is well worth the effort, and that support is available for those who wish to engage.

Comments are closed for this article!