The earliest recorded attempts at hip replacement date back to 1891. At the time, ivory was proposed to replace the femoral heads of patients whose hip joints had been destroyed by tuberculosis. Since then, everything changed. THINK speaks to the MaltaHip Team to learn about their innovative hip replacement technology.

In a constantly evolving world of medical devices, the MaltaHip Project presents an advancement in prosthetic technology that aims to tackle some of the persistent challenges associated with traditional hip implants. Requiring an interdisciplinary approach, the MaltaHip brought together Prof. Pierre Schembri-Wismayer (Department of Anatomy), Prof. Ing. Pierluigi Mollicone (Department of Mechanical Engineering), and Prof Ing. Joseph Buhagiar, Dr Ing. Donald Dalli, Dr Leonardo Fanton, and Prof. Ing. Bertram Mallia (Department of Metallurgy and Materials Engineering). This multidisciplinary team from the University of Malta is currently searching for a promising solution for millions suffering from joint-related issues globally.

The Need for a Biomedical Advancement

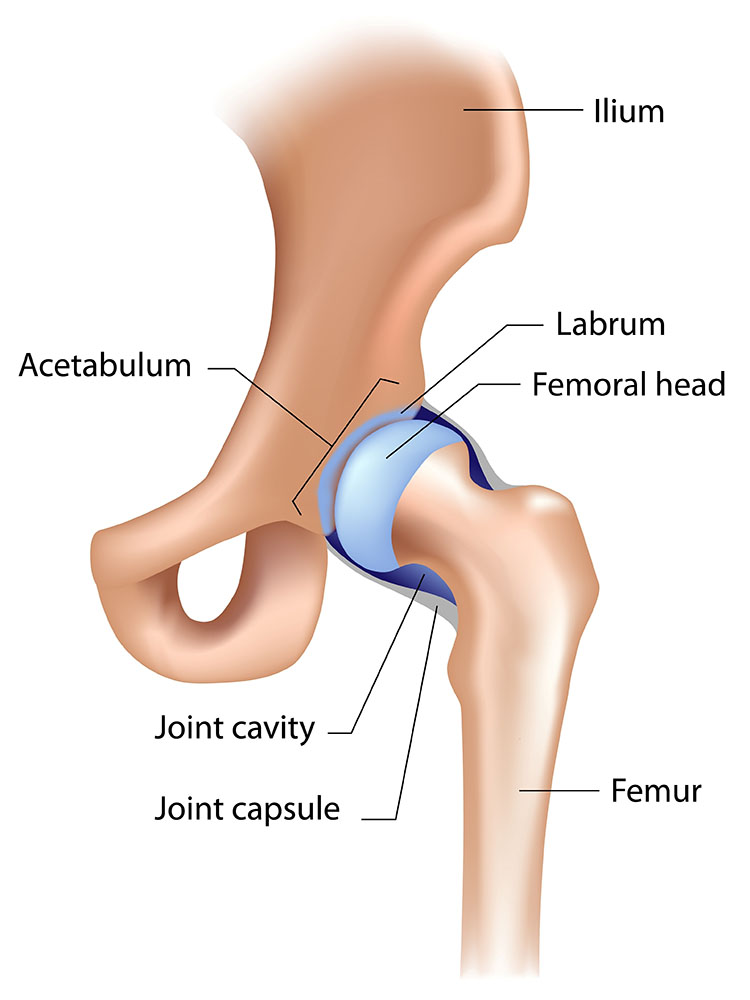

Joints, also known as articulations, are the points where two or more bones meet. By providing a connection between bones, joints provide the body stability and allow movement. However, several joint disorders can cause pain and swelling, thus reducing the range of motion.

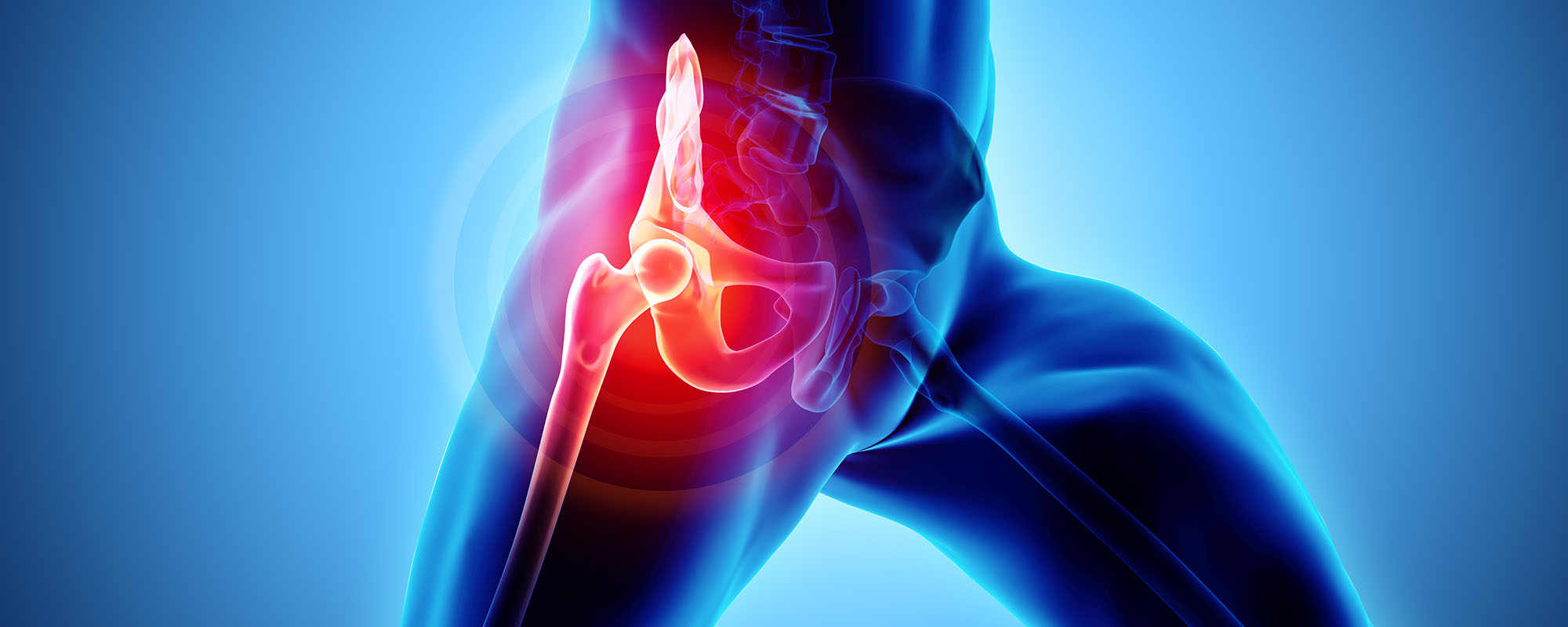

Ranking in the top three medical problems that afflict the population, arthritis is one of the leading causes of debilitating pain in Malta. This irreversible condition is caused by the slow degradation (or wear) of the cartilage that surrounds joints such as knees and hips. While some types of arthritis can be managed with painkillers, exercise, or other medications in their early stages, once the severe pain sets in, the only option is surgery.

Hip arthritis, as the name indicates, corresponds to the deterioration of the cartilage of the hip joint. The hip is a ball-and-socket joint with the ball at the top of the thighbone (the femoral head). The ball is separated from the socket (the acetabulum) by cartilage. The cartilage that coats the femoral head acts as a slippery coating between the ball and the socket, allowing the ball to glide and rotate smoothly when the leg moves.

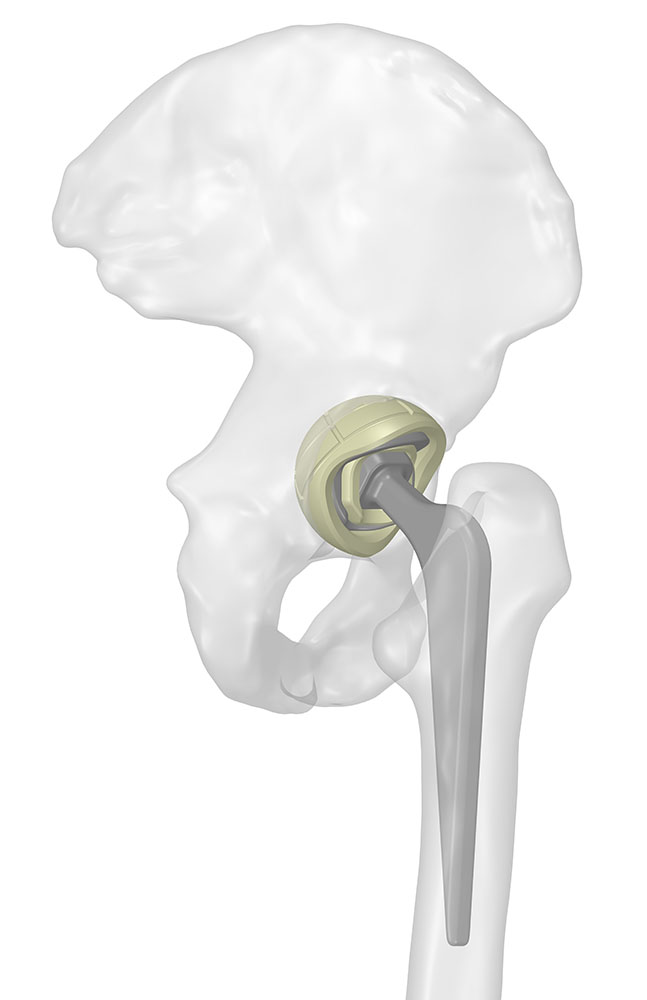

Right: The implant developed as part of the MaltaHip Project.

(Image courtesy of the MaltaHip Team)

When the cartilage in the hip is damaged or thinner, the space between the bones narrows. In advanced cases, the head of the thighbone and the socket rub against each other, likely resulting in chronic hip pain (due to joint damage) and difficulties walking or exercising (due to joint stiffness). In such cases, the most common recommendation is to remove the joint and replace it with durable prosthetic parts.

The Inspiration

In July 2014, a single observation from Prof. Pierre Schembri-Wismayer, a lead researcher and professor of anatomy, led to the development of the first-ever made-in-Malta hip joint replacement: why do ankle joints suffer less from arthritis compared to hips and knees?

‘It is known that ankle joints, which have simpler, flatter surfaces, experience much less arthritis compared to the joints with more spherical surfaces like the hip joint,’ explains Schembri-Wismayer. ‘This could explain why different joints are differentially prone to suffer from arthritis.’

According to Ryan Giordmaina, an orthopaedic surgeon who the MaltaHip Team and Garland Surgical Ltd consult with, hip prostheses commonly utilise a ‘hard-on-soft’ bearing configuration whereby the femoral head implant is made up of metal or ceramic, which articulates against a polyethylene acetabular cup. The spherical shape of the hip prostheses can result in a degree of wear over time, which may lead to inflammation and the need for revision surgeries. Therefore even current prostheses are vulnerable to wear and have a limited lifespan as a result.

The Design Concept and Overcoming Engineering Challenges

To overcome this problem, the MaltaHip takes a fundamentally different approach. Instead of a ball-and-socket design, the Team developed an implant with three cylindrical surfaces, each allowing linear movement in one direction. These surfaces are oriented at 90 degrees to each other, replicating the natural movements of the hip: flexion and extension (forward and backward), abduction and adduction (side-to-side), and internal and external rotation.

(Image courtesy of the MaltaHip Team)

During his time as a Research Support Officer, Dr Ing. Donald Dalli, one of the inventors and a mechanical engineer, played a pivotal role in turning this concept into a functioning prototype. ‘One of our main challenges was to integrate these cylindrical surfaces within the limited space of the hip joint while maintaining the necessary range of motion and durability,’ he says.

However, those were not the only challenges that the Team met. After talking with surgeons, the Team identified ‘a common problem with current hip replacements: the risk of dislocation, especially in the first year after surgery when patients are most vulnerable,’ explains Dalli. ‘So, it was crucial to develop a locking system that would prevent dislocation while maximising range of motion.’ This is known as an interlocking mechanism, which ensures that the components remain securely in place while allowing free movement. Implant prototypes showed excellent stability during laboratory testing and cadaveric surgeries. Implant prototypes showed excellent stability during laboratory testing and cadaveric surgeries.

Dr Leonardo Fanton, a postdoctoral researcher enrolled in a more recent stage of the project, remarks that the Team was recently working towards miniaturising the original prototype. ‘We needed to create smaller implants for different patient sizes while still maintaining the strength and durability of the device,’ Fanton explains. Through extensive iterations, the Team successfully designed smaller versions of the implant that meet rigorous mechanical requirements.

Material Innovation and Wear Reduction

The materials used in the MaltaHip Project are another area where the project excels. Since the MaltaHip uses already widely used commercial materials, no additional toxicity testing for new materials was necessary. Traditional hip implants often rely on metal and polyethylene (a type of plastic) to create the ball-and-socket structure. However, these materials wear down over time, especially in the spherical design, where the multidirectional forces create significant friction.

Fanton notes that ‘the polyethylene is more resistant to unidirectional sliding forces (like in the MaltaHip) because the polymer chains align to the direction of sliding, making the material harder in this direction.’ This alignment is never achieved in the traditional ball-and-socket implant, because the sliding direction is continuously changing.

‘The final design works together to replicate natural hip movements with minimal friction and wear, without changing the materials usually used,’ adds Prof. Ing. Pierluigi Mollicone, one of the inventors. ‘The linear motion aligns with the polymer chains in the polyethylene, which hardens the material and makes it more resistant to wear. This extends the life of the implant significantly,’ he notes.

(Image courtesy of the MaltaHip Team)

According to testing, the implant prototype showed three to four times less wear compared to conventional implants. This is a critical breakthrough, as wear is one of the primary reasons hip replacements fail over time.

Collaboration Across Disciplines

The success of the Malta Hip project is largely due to the interdisciplinary nature of the Team. With expertise ranging from mechanical engineering to biomedical science and clinical experience, the project brought together specialists from different fields to solve a common problem.

Project leader Prof. Ing. Joseph Buhagiar, who specialises in materials engineering, highlighted the importance of this collaboration. ‘The advantage of working in a relatively small but close-knit university like the University of Malta is that we can easily collaborate across disciplines,’ he says. ‘When you can walk over to the medical department and sit down with colleagues to discuss an idea, it really speeds up the innovation process.’

The Team’s work was supported by local manufacturing partners like EMPAV Engineering, a small yet highly advanced machining company in Malta that helped create the prototypes for testing. EMPAV’s precision engineering was vital in ensuring that the prototypes met the exact specifications required for medical testing.

The Road Ahead: From Prototype to Market

While the MaltaHip Project has made significant strides in development, there is still a long road ahead before the implant reaches the market. The Team is currently in the process of raising additional funds to conduct clinical trials and achieve regulatory approval. Simon Mifsud, the CEO of Garland Surgical Ltd, a company formed to commercialise the Malta Hip implant, explains the financial challenges: ‘We need around £2 million to finalise the development and another £10 million to complete the regulatory process with the FDA and European regulators.’

The regulatory process is rigorous, requiring extensive testing to ensure the safety and efficacy of the implant. So far, the MaltaHip implant has been successfully tested in cadaveric specimens and laboratory settings. The next step will be clinical trials in patients – a costly and complex process that requires significant investment.

Despite these challenges, the Team is optimistic about the future. The initial results have been overwhelmingly positive, with surgeons praising the ease of implantation and the potential benefits for patients. Mifsud emphasises the importance of getting the design right: ‘What we’ve developed is something that could potentially last a patient’s lifetime, reducing the need for painful revision surgeries and improving quality of life for people who need hip replacements.’ By rethinking the design of hip replacements, this multidisciplinary Team has developed a solution that promises greater durability, less wear, and enhanced stability for patients. The Malta Hip Project is a shining example of how innovation in medical technology can address longstanding problems.

The MaltaHip Team wishes to acknowledge the value in the setting up of the transdisciplinary research and knowledge exchange (TRAKE) complex at the University of Malta (ERDF.01.124), which is being co-financed through the EU through the European Regional Development Fund 2014–2020.

Further Reading

Fanton, L., Schembri Wismayer, P., Dalli, D., Mollicone, P., Mallia, B., Bartolo, M. K., & Buhagiar, J. (2024). Hip joint replacement based on linear cylindrical articulations for reduced wear: A radical change in design. Invention Disclosure, 4, 100030. https://doi.org/10.1016/j.inv.2024.100030

Comments are closed for this article!