3D printing can be an expensive sector to get into, but SPELL3D’s solution can help peel back some costs by combining the advantages of two styles of printer. The SPELL3D project is led by the University of Malta and coordinated by Prof. Arif Rochman from the Department of Industrial and Manufacturing Engineering, with Sarah Delia as the Research Support Officer alongside Prof. Ing. Pierluigi Mollicone from the Department of Mechanical Engineering and Dr Ing. Evan Dimech from the Department of Electronic Systems Engineering.

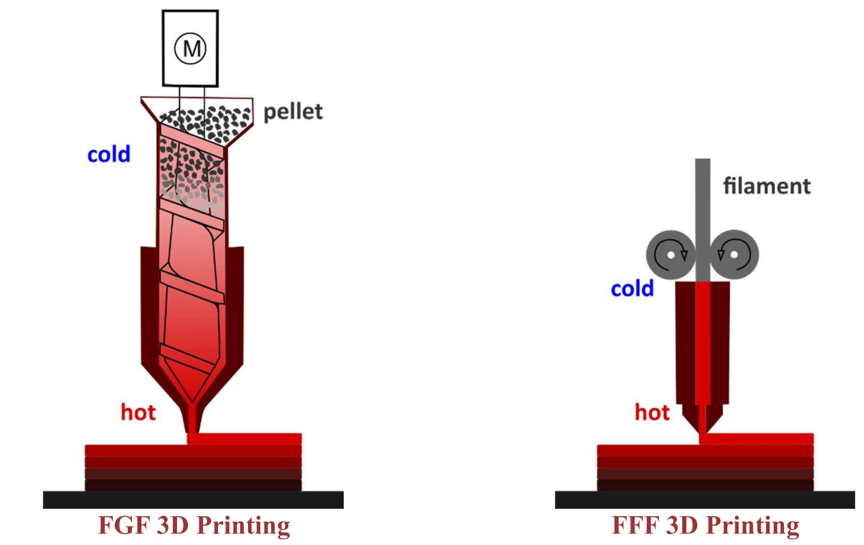

Additive manufacturing, more commonly known as 3D printing, is a technique which generates and produces parts using a computer-aided design (CAD) model or 3D digital model where material is deposited – or in technical terms, ‘extruded’ – in layers on a printing bed. The most common types of material extrusion used in 3D printing are fused filament fabrication (FFF) and fused granular fabrication (FGF). The FFF technology, also referred to as fused deposition modelling, uses filament material which is pushed through a heated nozzle to produce parts layer-by-layer. In contrast, FGF printers use polymer pellets which are melted and extruded using an extrusion screw which reduces material costs and enables freedom in material selection.

Sketched by Prof. Arif Rochman.

A majority of FGF printers are less suitable for desktop or consumer 3D printers since they are bulky and much more expensive compared to FFF printers. The SPELL3D research project aims to solve these issues by developing an innovative pellet extruder for a 3D printer that combines the advantages of FGF and FFF 3D-printing systems, allowing for cost-effective material selection and purchasing.

The SPELL3D extruder will allow for better polymer selection since these will be used as raw material in pellet form. SPELL3D is expected to require less material to be heated or melted, leading to lower energy consumption and fewer fumes generated. It will also not require a specialised extrusion screw design and will allow ease of creating a thermal balance between the hot and cold ends of the extruder. In addition, the SPELL3D extruder will have a quasi-linear relationship between the amount of the fed solid material and the extruded melt. The benefits of SPELL3D will extend to society as well, as SPELL3D printing will lead to reduced environmental impacts. These advantages make SPELL3D an attractive choice for 3D printer users, enhancing both efficiency and product quality.

This project is in collaboration with industrial partner Invent3D, with David Sciberras as the Co-Founder and Chief Executive Officer. Invent3D is Malta’s largest 3D printing farm, containing around 200 3D printers which vary in shape, size, and design depending on the material, motion system, and number of axes, extruders, or nozzles, and type of user interface. Being specialists in the world of additive manufacturing, Invent3D was and is involved in several research projects related to 3D printing and product development for various industrial sectors such as construction, healthcare, aerospace, and automotive.

For more information on the SPELL3D project: https://spell3d.com/

The project is funded for three years by MCST through the FUSION: R&I Technology Development Programme (R&I-2022-010-T).

Comments are closed for this article!