While the advent of 3D metal printing may redefine how designers develop parts for products, the process itself is not without faults. Andre Giordimaina speaks with THINK about the GLAM Project, which aims to improve the process of 3D metal printing by optimising the finish and performance of designed parts.

3D printing with metal allows designers to completely reshape how crucial engineering components are designed and manufactured. Parts for aircraft can be designed without the constraints of traditional manufacturing methods, minimising weight without sacrificing structural integrity, thereby reducing fuel emissions and improving efficiency. Medical implants, such as hip and jaw repairs and replacements, can be customised to the exact bone structure of every individual patient with minimal effort and zero additional costs.

However, like all manufacturing methods, 3D metal printing has its own constraints and potential drawbacks. One of these ongoing challenges remains the relatively poor surface finish. The layer-by-layer nature of additive manufacturing (as it is often referred to in industry) results in rough surfaces that require post-processing. A smoother finish would not only enhance part aesthetics but also improve performance, reducing friction and wear in mechanical applications. This article explores the research being carried out by Dr Andre Giordimaina, Prof. Ing. Glenn Cassar, Prof. Arif Rochman, together with Dr Ing. Bonnie Attard in the Green Laser post-processing in Additive Manufacturing, or GLAM, Project aimed at improving the surface finish of 3D metal printed titanium components.

Setting the Stage: The Rough Reality

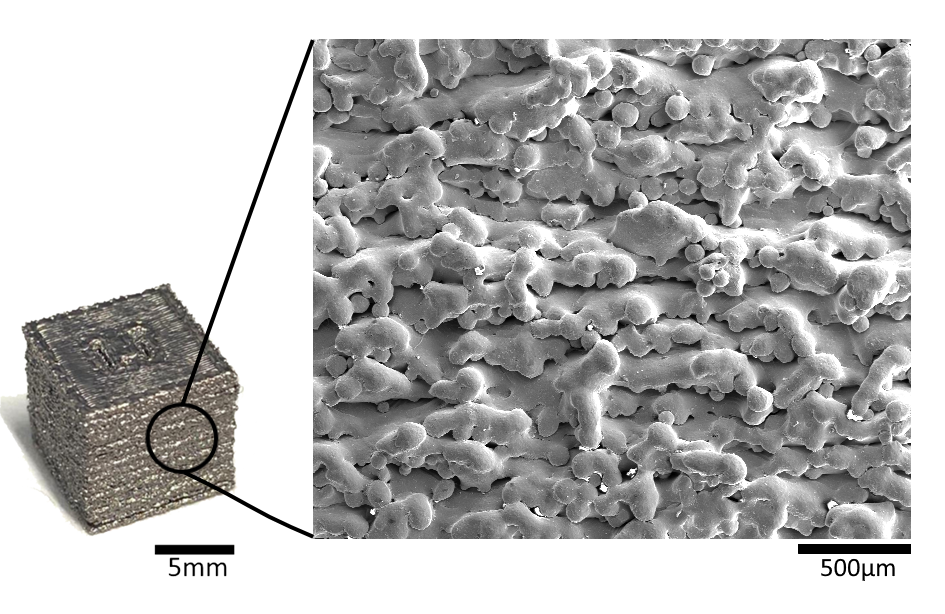

Electron beam powder bed fusion (EB-PBF) is a type of additive manufacturing process, that uses a high-energy electron beam to fuse metal powder, layer by layer, to create parts. A very thin layer of metal powder is spread over a metal build plate, and an electron beam follows the patterns according to a 3D digital file, selectively melting the powder into the shape of a single ‘slice’ of the part. A new layer of powder is then spread over the previous layer, and the process is repeated until the parts are completed. When the build plate is removed from the machine, the parts are surrounded by loose or partially melted powder. Most of the powder attached to the parts can be easily removed and recycled using high-pressure air jets. The top surfaces are not in contact with any powder and remain smooth. However, some particles partially melt and become embedded in the sides of the part, making them rough to the touch. The surface of the part are characterised by microscopic jagged edges and protruding powder particles, which increase the friction and wear on the part when in contact with and moving against other surfaces. This decreases the overall operational life of the part through a phenomenon known as fatigue – where repeated mechanical stresses cause cracks to form at the surface; eventually leading to failure.

Image courtesy of the GLAM Team

The GLAM project aims to advance the EB-PBF process by improving part surface quality after manufacturing. This was achieved by changing the EB-PBF machine printing parameters followed by a suitable chemical immersion process.

From Rough to Refined: Results and Insights

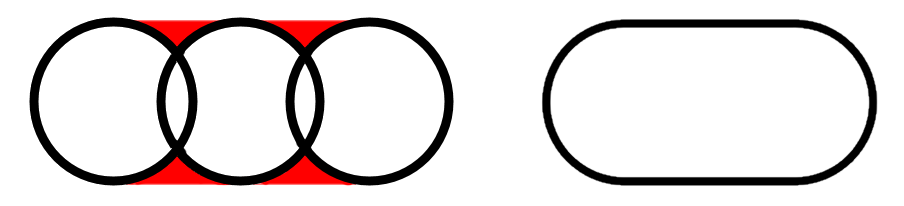

When creating the sides of the part, the standard technique is to use ‘multispotting’, where the beam is divided into several spots that form the edge of the part almost instantly. This is possible because the electron beam is controlled by inertia-free magnetic lenses, allowing rapid back-and-forth movement of the beam at different spots. This is meant to quicken the manufacturing process; however, powder is left solid in the spaces between spots, which eventually form gaps and defects on the part surface. Instead, an alternative technique called ‘continuous contouring’ can be used. With this technique, the beam moves consistently, melting the powder in straight lines instead of being divided into several spots. This prevents gaps and defects from forming on the surface, significantly smoothing the part.

Right: An example of a surface when using continuous contouring

Image courtesy of the GLAM Team

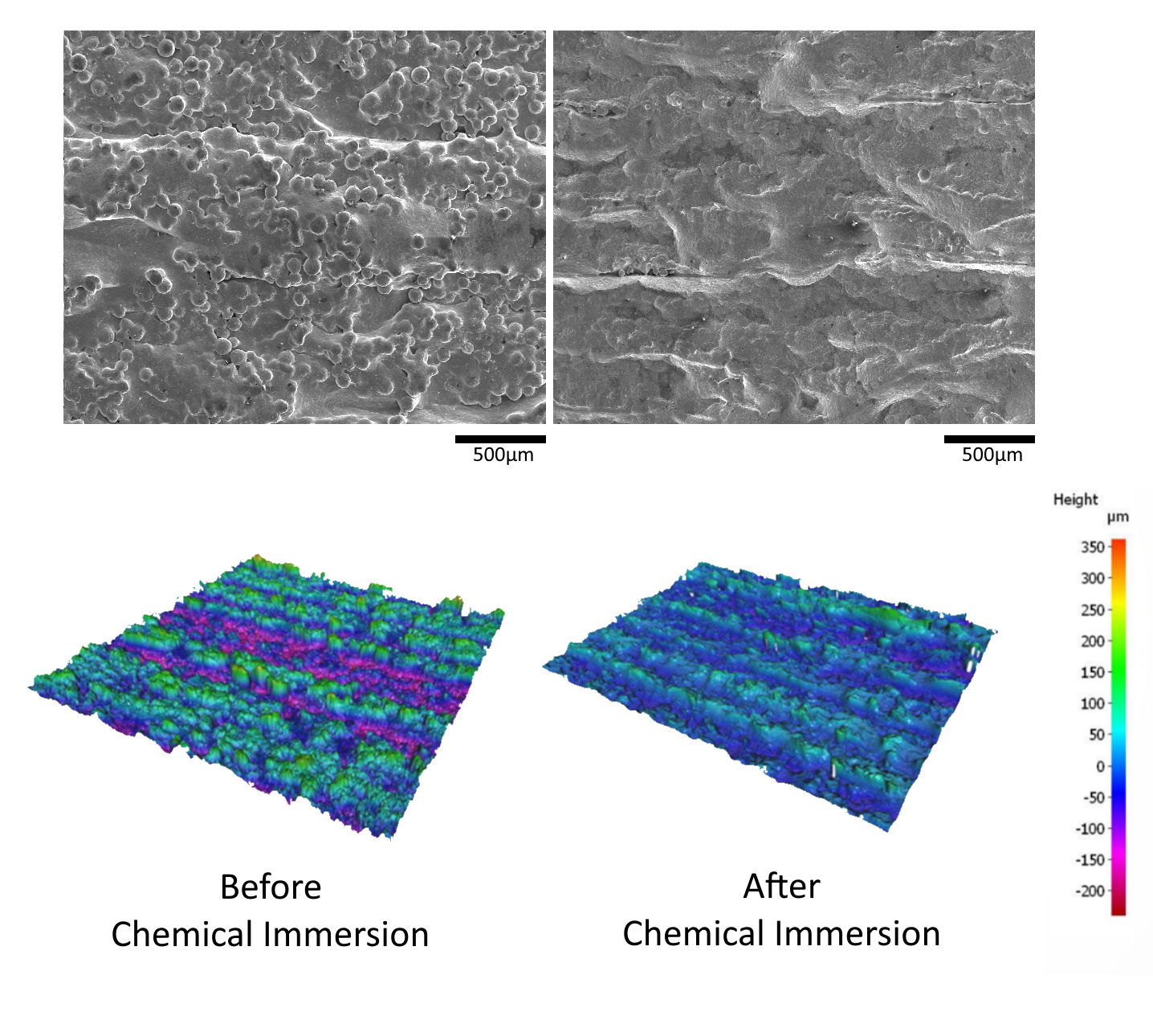

Post-processing chemical immersion after additive manufacturing can improve the part surface finish. This involves submerging the parts in a dilute hydrofluoric acid for 2 hours (long durations were needed to reduce the roughness significantly). This dissolves the surface of the part, removing particles stuck to the surface and smoothing irregularities. The height differences between the topographical peaks and troughs are also reduced, making the surface smoother and uniform.

The chemical immersion technique can offer advantages over mechanical polishing techniques. The acid dissolves the part surface relatively uniformly, which is well suited for parts’ complex and delicate geometries or hollow internal structures such as cooling channels.

According to research performed by the GLAM project so far, using a combination of continuous contouring and chemical immersion, surface roughness is reduced by approximately 33% compared to as-built surface using the industry-standard multispotting technique. The next phase of this project will focus on evaluating the mechanical performance of parts produced using this optimised combination of techniques. The researchers aim to observe and quantify any improvement in mechanical performance (primarily fatigue) thanks to the optimised part surface finish.

Left: As-built EB-PBF surface using continuous contours.

Right: Identical surface after chemical immersion.

Image courtesy of the GLAM Team

For more information on the GLAM project: https://www.facebook.com/um.glam

If you’d like to read more about the advances in 3D printing technology, THINK recently published two articles on this! Check out:

– Designing the Next Dimension: An Insight into 3D Printing Innovation

– 3D Printing Balloons Inflates Enthusiasm for Future Technology

The GLAM Project (SINO-MALTA-2022-13) project is financed by XJENZA, Malta, and the Ministry for Science and Technology of the People’s Republic of China (MOST), through the SINO-MALTA Fund 2022 (Science and Technology Cooperation).

Comments are closed for this article!