Aluminium alloys have a low density and are easy to make. These qualities make them popular in the transport industry which can range from cars to planes. A low density makes them perfect to reduce weight in large metal structures. Unfortunately due to poor wear resistance, aluminium alloys can deteriorate quickly which severely limits their applications.

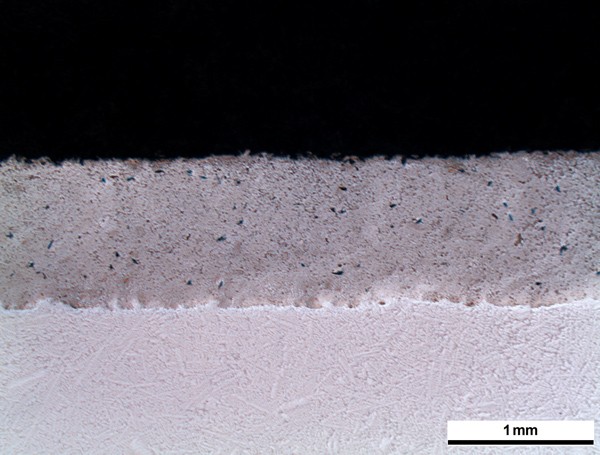

Dr Clayton D’Amato (supervised by Dr John C. Betts and Dr Joseph Buhagiar) modified the surface of an aluminium alloy (called A356) to overcome such limitations by improving wear resistance. D’Amato used a high power industrial CO2 laser to rapidly melt specific regions of the alloy’s surface. He simultaneously introduced additional alloying elements in the melt pool, which mix with the base metal to form new compounds that reinforce the soft aluminium surface. In this way, he formed a strong composite modified surface. Additional experimentation allowed D’Amato to reduce the loss of material due to wear by about 20 times. He optimised the conditions needed to laser process the surface of the aluminium in a uniform and repeatable manner. Adding nickel increased surface hardness 7-fold due to formation of aluminium-nickel compounds. Additional strength was achieved by adding hard ceramics to this aluminium-nickel structure. D’Amato created fine titanium carbide (TiC) particles in a matrix structure (pictured) by alloying a mixture of nickel, titanium and carbon (Ni-Ti-C). Aluminium treated in this way was much stronger.

The exact hardness was related to the mix of alloying elements in the modified surfaces. Hardness improved wear resistance, with large improvements in both surfaces alloyed with nickel and Ni-Ti-C. They lost 20 times less material than normal aluminium preventing severe damage.

Using a high powered laser allows improved wear resistance just where needed. This saves costs and increases versatility. The above technique could be used to manufacture aircraft pump parts, fittings and control parts, and in automotive water-cooled cylinder blocks.

This research was performed as part of a Ph.D. in Engineering within the Faculty of Engineering at the University of Malta. It was partially funded by the Strategic Educational Pathways Scholarship (Malta). This Scholarship is part-financed by the European Union — European Social Fund (ESF) under Operational Programme II — Cohesion Policy 2007–2013, “Empowering People for More Jobs and a Better Quality Of Life”. The laser processing equipment used in this project was financed by the 4th Italian protocol whilst the characterisation equipment was financed by the European Regional Fund (ERDF) through the project “Developing an Interdisciplinary Material Testing and Rapid Prototyping R&D Facility (Ref. no. 012)”.

Comments are closed for this article!