Discover how resourcefulness and innovation in repurposing materials like broken glass, tiles, and eggshells can lead to the creation of everyday objects. Explore the collaborative effort of first-year B.Sc. (Built Environment) students under Prof. Ruben Paul Borg’s guidance as they transform waste into functional and aesthetically pleasing concrete flowerpots. Dive into the journey of producing durable, eco-friendly flowerpots that showcase the power of creativity and sustainability in construction practices.

Broken glass, tiles, aluminium cups, and eggshells might not be thought of as materials that can be repurposed directly by households. Nonetheless, a -fusion of ingenuity and creativity can lead to repurposing this waste to make everyday objects! The practical component of Prof. Ruben Paul Borg‘s study-unit on Materials and the Environment allowed us first-year B.Sc. (Built Environment) students to explore the possibility of using waste materials as ingredients in producing concrete. This activity resulted in the production of an array of flowerpots, which help in reducing the carbon footprint of concrete manufacture. Considering that after water, concrete is the second most consumed substance in the world, and it the most widely used material in the construction industry with a large carbon footprint (the cement industry is responsible for 8% of global carbon emissions!) – every little bit can help. In exploiting waste or industrial byproducts, more durable concrete can be produced, less non-renewable resources are consumed, whilst waste disposal is reduced through recycling.

Concrete is made by combining cement with aggregate, water, and admixtures. Admixtures are special materials added to the concrete mix in small quantities to enhance its workability, durability, or performance. Concrete aggregate consists of geological materials such as sand and gravel, while cement is produced from limestone and clay at high temperatures. The aim of the flower pot project was to replace a portion of this aggregate or cement with our selected waste materials in order to produce concrete flower pots. In spite of being based on waste, the flower pot as a functional object also had to have high aesthetic qualities. Achieving more with less! The class worked in small groups, with our group opting to combine two waste materials: crushed eggshells and aluminium tealight cups cut into strips. The cement, water and aggregate were mixed, replacing part of the aggregate and cement with the selected waste material. Once the mixture was homogeneous, it was cast in the mould. The mould used was a salvaged plastic bin with a hollow square pattern, selected to give an aesthetic motif to the final product. This was sealed with tape to make it watertight, and the mixture was cast inside to take the shape of a flower pot. The concrete was allowed to set and cure for several days to gain strength. The pot was then demoulded and sanded down to create a smooth internal surface and rim.

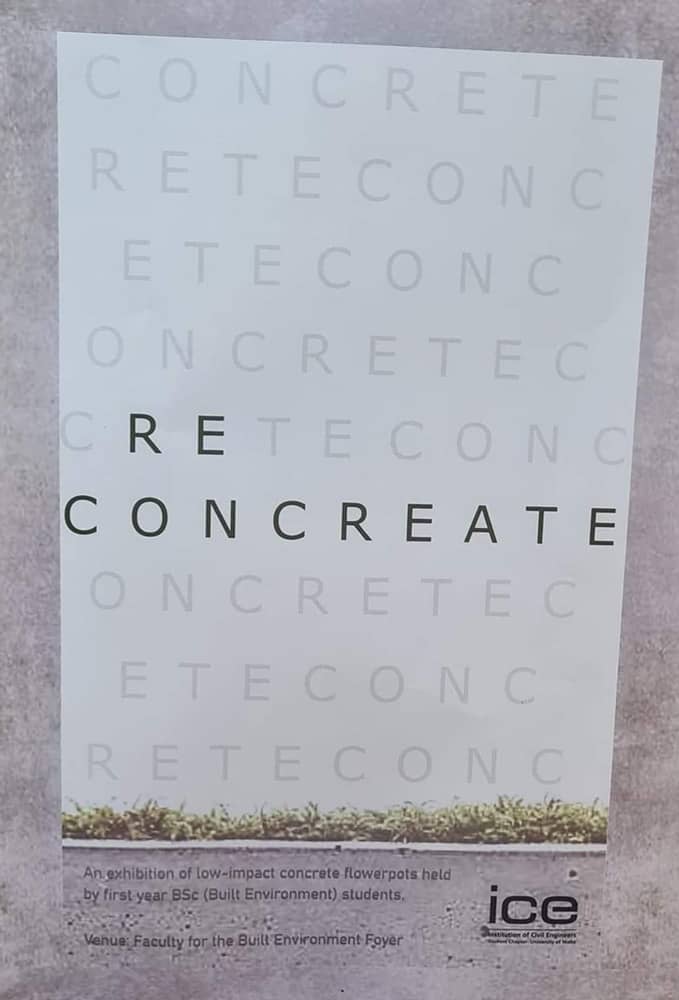

Other groups followed similar procedures to create their own flower pots with a wide variety of waste materials, including crushed glass, tiles, and shredded tyres. All the flower pots produced from this module were on display as part of an exhibition on Decarbonisation and Construction Materials, held at the Faculty for the Built Environment, alongside posters detailing information on how each piece was created. The annual flower pot activity supports initiatives in learning about concrete as an important and complex composite material, whilst also ensuring an understanding of the key role of the construction industry in addressing the Sustainability Development Goals and Climate Neutrality targets.

Images courtesy of Prof. Ruben Paul Borg

Comments are closed for this article!