Limestone is precious to Malta. The softness of the stone makes beautiful sculptures but also erodes quickly. Jessica Edwards caught up with Dr Daniel Vella and Prof. Emmanuel Sinagra to find out how limestone and Malta’s heritage can be protected.

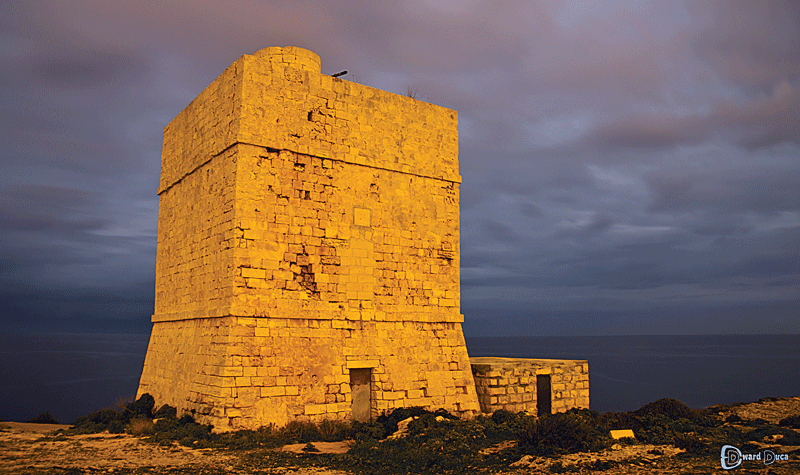

Walking through a historical city, seeing all the old buildings and statues, how are they still in such an exceptional condition? Or, imagine you need to renovate an old house in Mdina, or the Neolithic temples in Tarxien, or the over 100-foot high bastions around Valletta. These structures all need stone conservation.

Walking through a historical city, seeing all the old buildings and statues, how are they still in such an exceptional condition? Or, imagine you need to renovate an old house in Mdina, or the Neolithic temples in Tarxien, or the over 100-foot high bastions around Valletta. These structures all need stone conservation.

Stone conservation is a complex science. Two methods used to conserve and/or restore stone are consolidation and cleaning. Limestone is soft and deteriorates by weathering. This erosion is caused by natural phenomena: wind, rain and salt crystallisation—very common in Malta. The salt may come from fog or sea spray, or even from rising damp with the salt dissolved in water. If the water evaporates on the stone’s surface it is harmless (efflorescence), but if it crystallises below the stone’s surface (inflorescence) it is a very different issue. Then salts crystallise in the stone’s pores, where they apply pressure on the surrounding pore walls that eventually breaks the structure down causing the stone surface to flake.

This is the purpose of a consolidation, which is the application of a material on a stone’s surface to bind the deteriorating outer layers with the ‘healthier’ inner stone. The consolidant restores its mechanical integrity. But how do conservators know which material to use? Dr Daniel Vella, Prof. Emmanuel Sinagra and their teams at the University of Malta are testing consolidants to find the best ‘glue’ for local limestone. Before his work at the University of Malta, Vella worked for nine years with Heritage Malta teaching conservation students the science behind the practice. His Ph.D. involved applying transparent protective coatings to historical steel objects. After his Ph.D., Vella teamed up with Sinagra to work on stone conservation and, in doing so expanding his research portfolio.

“A consolidant needs to seem invisible, not be noticeable”

One of the first chemicals used for consolidation were organic polymers (polymers are chains of the same molecule strung together). Substances such as acrylic, PVC, and epoxy were used as consolidants. The problem is that these materials degrade with time and change to a yellowish colour. A consolidant needs to seem invisible, not be noticeable.

Old Maltese houses are built of limestone. Limestone is porous, with water and its dissolved salts passing through it. This continuous passage of water is needed in old houses to prevent salt build up. Another problem of organic polymers is that they prevent the free passage of water through the stone. The salt deposits end up forming beneath the consolidant. Accumulation of salt eventually pushes out the consolidant along with a thick layer of stone. Modern houses are damp proofed with a thick layer of tar so that the water never reaches the stone walls, eliminating the problem completely.

Vella and Sinagra’s research focuses on a new breed of consolidants that provide mechanical support for the stone, but allow it to breathe allowing water to pass through it along with dissolved salts. These polymers are not organic but instead based on lime (calcium oxide, used in concrete and mortar) or silica (Silicon dioxide, used to make glass and microchips). Silica consolidants will be discussed later, lime works by first being used to coat walls after being made into a coarse lime slurry that is applied to the stone. This blocks the pores but the stone still remains porous. ‘The advantage of lime is that if it is used as a consolidant it can also be used as a sacrificial layer,’ Vella explained. This approach was used back in the 15–18th century by the Knights of St John. The lime was applied as two thick layers together with a colour pigment. The second layer acted as a protective layer from salt crystallisation within the stone, which causes the outer layer of the consolidant to eventually fall off. If the outer layer does fall off it can easily be reapplied.

Lime dissolved in water is one consolidant Vella and Sinagra are investigating. Limewater (calcium hydroxide) works by entering the stone where it reacts with carbon dioxide being transformed into calcium carbonate, limestone itself. The downside of limewater is that large amounts are needed because lime does not easily dissolve in water. Improving the solubility of lime would turn it into a much better consolidant for stone conservation and restoration. One solution is nano-limes, so named due to their small size. These small particles are so tiny that they can remain suspended in the water for a long time without settling, allowing much more lime to be applied to the stone.

Nano-limes are already available commercially. Tests by Prof. JoAnn Cassar (Faculty of Built Environment, University of Malta) and her team showed that these limes are not always as small as is claimed on the packet. Commercial

nano-limes do not always penetrate local limestone even though they should be small enough to do so.

“In large amounts, hexane is a health hazard to the conservator”

To control the nano-lime’s size, chemistry student Duncan Micallef created a micro-reactor. Micro-reactors are confined spaces used to make particles of a specific size. He created a micro-reactor out of a micro-emulsion, a liquid mixture of water in hexane. Hexane is not soluble in water, forming tiny droplets, like the fat droplets in milk. He grew his lime nanoparticles in these tiny droplets. Micallef grew 10-20 nm nano-lime particles, around an order of magnitude smaller than commercial products. These nano-limes could pass through stone pores and properly consolidate local stone—problem solved.

Micallef dissolved his nano-lime in hexane—a toxic compound—creating another problem. In large amounts, hexane is a health hazard to the conservator.

The next stage is to find a harmless solvent to dissolve the nano-lime. An ideal consolidant would be a liquid that when placed inside the stone polymerises becoming solid. The consolidant should also line the internal stone pore structure rather than fill up pore space as happens with organic polymers. Vella researched salts that are basically liquid glass. The starting material is a liquid precursor molecule containing silicon-tetraethoxysilane—a modified form of silicon. With the addition of water this molecule reacts to form silica nanoparticles (~4 nm diameter) small enough to seep through the limestone pores and polymerise. This consolidant nicely lines the stone’s pores rather than blocking them.

Silica consolidants suffer from weak chemical binding with limestone. Silica is not chemically attracted to the calcium carbonate that makes up limestone. The stone needs a ‘guru’ (a primer to help it bind) to be consolidated. One ‘guru’ is pre-treating the stone with ammonium tartarate. This primer reacts with the stone forming a layer of calcium tartarate, which silica consolidants can react with forming a stronger bond and improving the mechanical integrity of the stone. The only problem is that the reaction does not occur easily. Vella, Sinagra, and their team are working on making new silica-based molecules that can be more effective. Their student, Sophie Briffa, tested the ammonium tartarate primer and is planning to improve silica-based consolidants by having the primer attached to it. This would reduce the number of steps simplifying the procedure to conserve or restore limestone.

Apart from consolidation, the stone must be cleaned. The requirement to clean a building is usually motivated by the aesthetic benefit. Stains of iron (III) oxide, or rust, are the most common stains, these usually give the stone a reddish colour. Rust has a very low solubility in water which means it is incredibly difficult to wash away. The ochre decorations at the Hypogeum would probably have been lost otherwise. Looking over the bastions of Mdina, some of the stone appears reddish due to this. One way of removing these stains is through the chemical reduction of iron (III) to iron (II) by using a mild reducing agent followed by a chelating agent that traps the heavy metal, the iron. Vella and Sinagra used a similar method to remove copper stains, were they used an amino acid called glycine as a chelating agent, which worked in cleaning the copper.

Malta’s limestone heritage can be kept alive. The methods Sinagra and Vella are researching still need refining before they can be applied in the real world. What would Malta be like if it lost the bastions of Valletta or Birgu’s houses, not to mention the churches and chapels all over the Islands? Heritage denotes the history of a place, its identity: a projection of Maltese culture.

Comments are closed for this article!