By Robert Zammit

By Robert Zammit

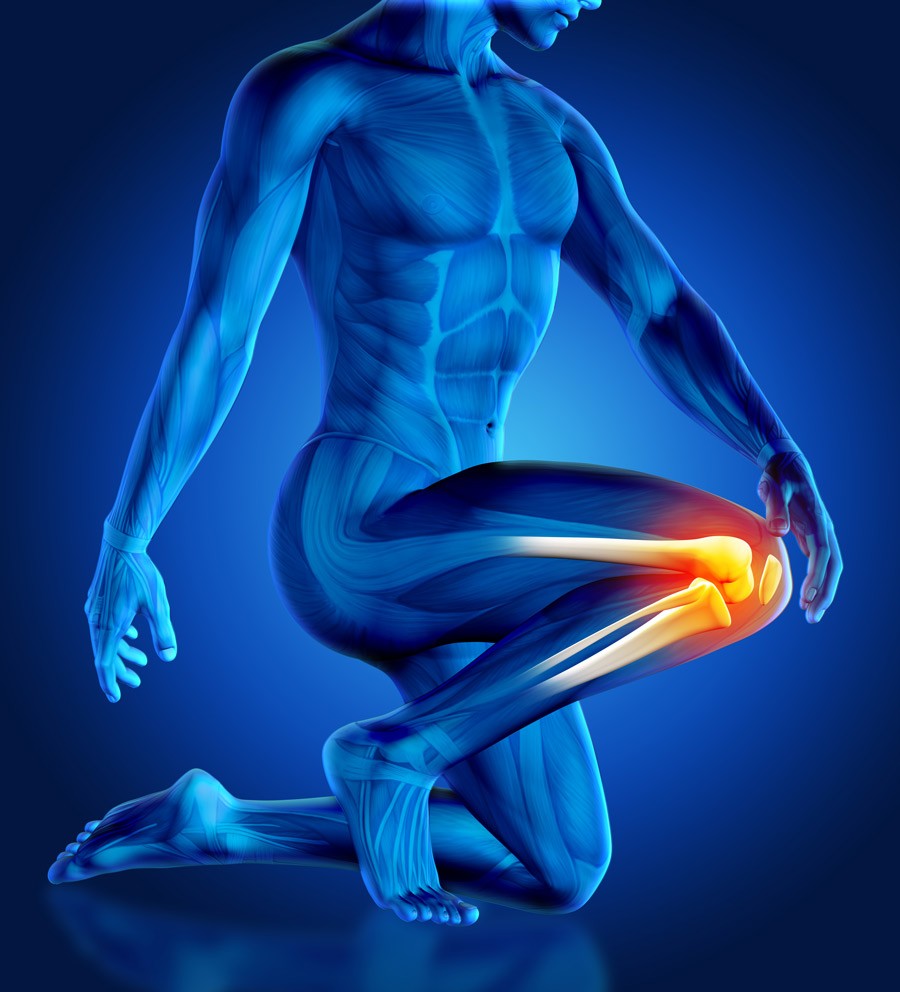

One of the most common causes of total knee replacements is osteoarthritis, a disease which affects around 40% of Maltese senior citizens. The rise in age expectancy and obesity, compounded by injuries to patients, will see these numbers grow. All of this is expected to increase total knee replacement surgeries by 362% by the year 2030. The need for knee implants to have a longer lifetime is real.

Currently knee implants consist of three components: the tibial component, tibial insert and femoral component, with metal-on-polymer articulation that is known to have poor wear resistance. This not only leads to implant failure due to excessive wear after a decade but studies also show that 19% of knee replacement patients are dissatisfied with the result of their surgery. One of the main reasons for this is that modern implants do not offer optimal fit, creating problems such as pain and motion limitation, which results in the knee implant being replaced.

I (supervised by Dr Arif Rochman) designed a knee implant to improve on the shortcomings of contemporary knee implants. The principal research aim was to study the design of 3D-printable patient-specific knee implants that have a longer lifetime. This was done by designing a patient-specific knee implant with two metal mounting components and two polymer articulating components, meaning that polymer-on-polymer articulation was used.

The experiments showed that high performance polymers experience lower wear rates compared to conventional materials. Innovative assembly features were designed to join the polymer articulating components with metal mounting components for easy assembly and disassembly. Similarly, an improved fixation technique was used to secure the metal mounting components with the patient’s bones. Stress analyses were then completed on the newly designed knee implant, which ensured that failure will not occur when implanted. Besides eliminating pain and motion limitation, the knee implant is expected to provide a more natural feel as it replicates the original knee joint geometry. Cowles, a patient who underwent surgery using a patient-specific knee implant says that ‘if I didn’t see the scar on it, I would assume it was my normal knee’.

Comments are closed for this article!